ULTEM: properties and applications of this high performance thermoplastics

High performance 3D printing polymers and materials: PEEK, PEI, PEKK, ULTEM

High performance thermoplastics are materials with superior properties compared to common thermoplastics. High-performance 3D printing materials are in fact designed to have high mechanical, thermal, chemical or electrical performances, and are therefore suitable for a wide range of advanced 3D printing applications. High-performance thermoplastics are often used in 3D printing applications that require high operating temperatures, corrosion resistance, mechanical strength, or advanced dielectric properties.

What are the best high performance thermoplastics? In the category of semi-crystalline thermoplastic materials we find polyethereketone (PEEK), while among the amorphous thermoplastics we find polyetherimide (PEI) and polyetherketonketone (PEKK).

In this article we have explained what is the difference between PEEK and PEKK, but now let's see what ULTEM is and what it is used for.

What is ULTEM and what is it used for?

ULTEM, a proprietary brand of SABIC, is a high-performance thermoplastics that offers a unique combination of thermal resistance, dimensional stability, chemical resistance, and electrical insulation. This type of polymer, used in various industrial applications including automotive, aerospace, electronics, medical, is able to withstand high temperatures and chemical agents, including organic solvents, oils, acids and bases.

Applications and uses of ULTEM in industry

ULTEM finds application and use in different sectors and industries where a combination of high thermal, mechanical and chemical performance is required together with electrical insulation and resistance to chemical agents. Some of the major applications of ULTEM include:

- ULTEM in the automotive sector: ULTEM is used for the production of light structural parts, such as engine mounts, exhaust system components, interior panels, electrical connectors and parts for cooling systems;

- Use of ULTEM in Electronics: ULTEM is used to produce electrical connectors, sockets, housings for electronic devices, components for printed circuit boards (PCBs), transformer coils and other parts that require high thermal resistance, electrical insulation and dimensional stability;

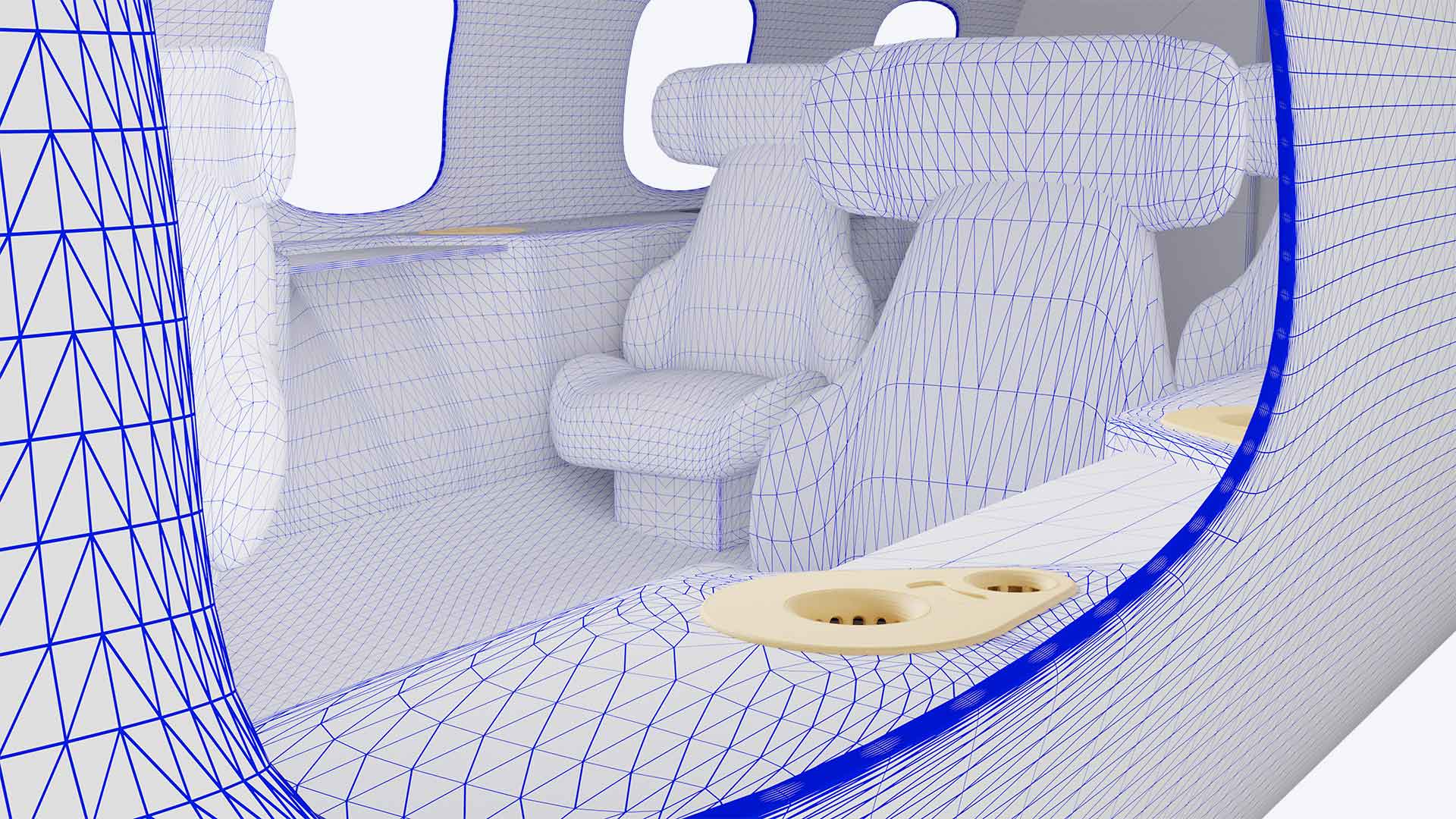

- ULTEM in the aerospace sector: thanks to its thermal and mechanical resistance, ULTEM is used for the production of aircraft components, such as internal and external parts of engines, structural parts, electrical connectors, fluid pipes and components for the exhaust system;

- ULTEM in the medical sector: ULTEM is used in the production of medical devices, such as imaging devices, surgical instruments, valves and dialysis equipment components, due to its chemical resistance, biocompatibility and sterilization ability;

- ULTEM in the chemical industry: ULTEM finds application in the production of pipes, valves, fittings and other components that require chemical resistance to corrosive agents and high temperatures.

The ULTEM polymers family includes several variants, each with specific properties, including:

- ULTEM 1000, the base polymer;

- ULTEM 1010;

- ULTEM 2300;

- ULTEM 9085.

What is the difference between ULTEM 2300 and 1000?

ULTEM 1000 is a standard form of polyetherimide with good mechanical and thermal properties. ULTEM 2300 is glass reinforced to increase stiffness and mechanical strength.

What is ULTEM 1010?

ULTEM 1010 is commonly used in industries such as aerospace, automotive, electronics, medical and industrial. Its high performance characteristics make it suitable for applications such as structural components, electrical connectors, circuit boards, automotive parts and other demanding applications that require durability, chemical resistance and thermal stability. It has low moisture absorption, which helps maintain dimensional stability even in humid conditions.

ULTEM 9085: material properties, datasheet, applications

ULTEM 9085, due to its excellent combination of properties, is among the best-known FFF 3D printing filaments in the industry. ULTEM 9085 consists of PEI blended with a polycarbonate copolymer, which modifies its properties to be more in line with the needs of industries with special requirements such as aerospace and defense. Therefore, ULTEM 9085 belongs to the family of polymers known as high-performance thermopolymers or superpolymers.

Its chemical structure consists of repeating units of an imide group (-C(O)NH-) and an ether group (-O-) within its polymer chain.

What are the features of ULTEM 9085?

ULTEM 9085 is used in a wide variety of applications. Some of the main features of ULTEM 9085 are listed below:

- High Temperature Resistance: ULTEM 9085 offers outstanding thermal resistance, with a heat deflection temperature (HDT) of 175°C. This means that it retains its structural strength even at elevated temperatures, making it suitable for high temperature applications;

- Mechanical resistance: This material offers good mechanical resistance. It features a combination of stiffness and flexibility, making it suitable for structural components and applications that require strength;

- Chemical Resistance: ULTEM 9085 is known for its excellent chemical resistance. It can withstand a wide range of chemicals, including solvents, acids and bases, without undergoing significant degradation. This property makes it suitable for various industrial applications which require good chemical resistance;

- Flame resistance: ULTEM 9085 has good flame resistance and meets various flammability standards, such as UL94 V-0. This means it is self-extinguishing and can be used in applications requiring increased fire safety;

- Dimensional Stability: ULTEM 9085 offers good dimensional stability, which means that parts made with this material retain their size and shape even in high temperature environments.

ULTEM 9085: applications and uses for 3D printing

ULTEM filament is used in a wide range of industrial applications, here are some examples:

- ULTEM 9085 for Aviation and Space Industry: ULTEM 9085 is a material widely used in aviation and space industry. Its characteristics and properties make it suitable for many applications in this sector. An example are the internal components of helicopters where, combined with industrial 3D printing systems such as Roboze solutions, it has the ability to offer end users an 80% reduction in procurement times;

- ULTEM 9085 for the railway industry: ULTEM™ AM9085F has been designed for aerospace use but is also used in other sectors, for example for the production of spare parts for passenger cabins in railway transport systems. In this case the main characteristics of interest are the EN45545 certification provided by Sabic and the low FST rate (Flame, Smoke, Toxicity), since in the event of a fire in the cabin, the material would not further endanger passengers;

- ULTEM 9085 for the Energy Industry: ULTEM 9085's excellent resistance to chemicals, hydrocarbons and high temperatures makes it suitable for applications in the oil and gas industry. It is used in drilling tools, valves, gaskets and connectors. Roboze 3D printing enables decentralized and on-demand manufacturing capabilities, which can be especially beneficial in remote or offshore locations, reducing reliance on external suppliers and risks associated with delays and transportation.