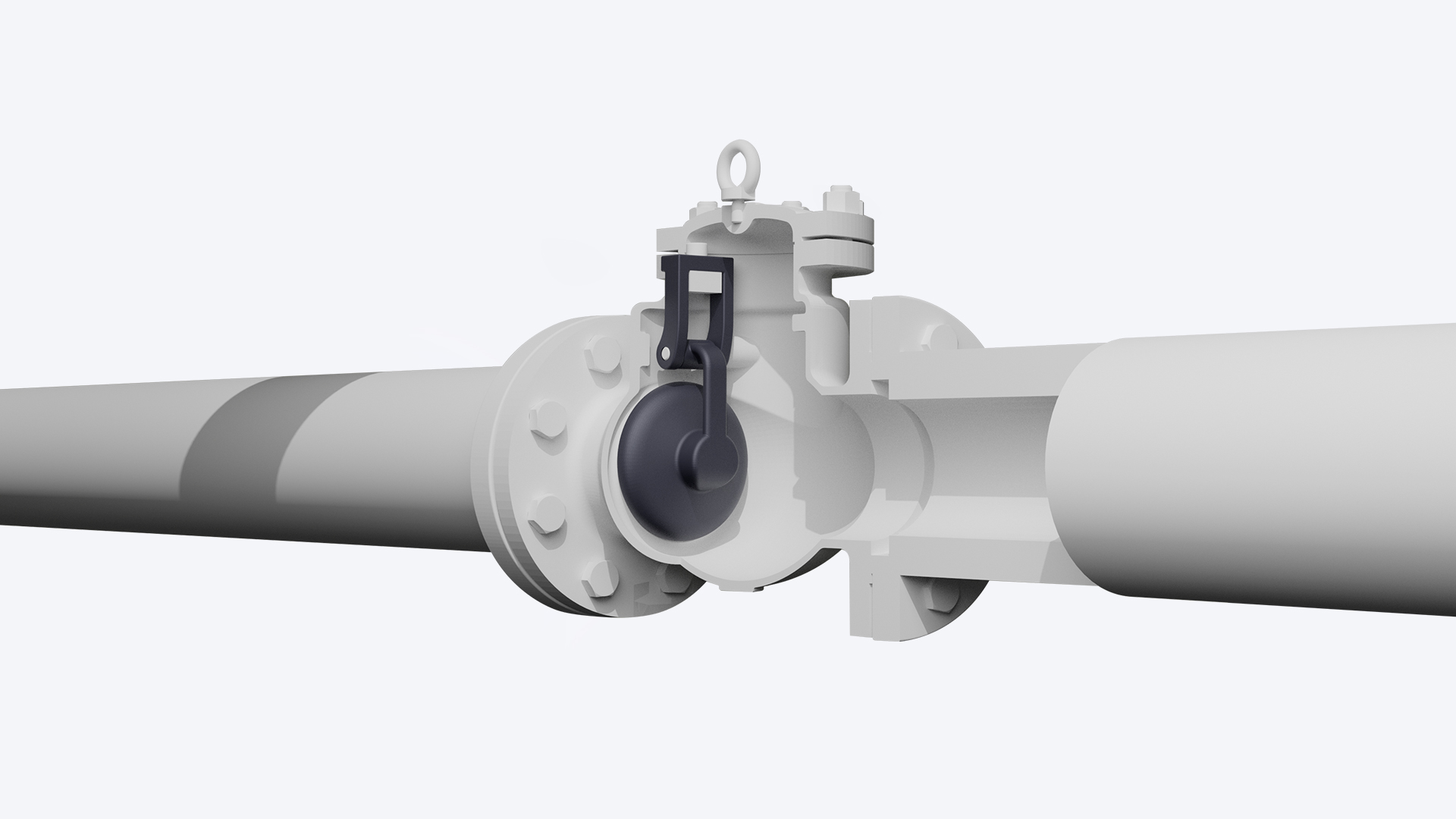

Production of swing check valves trim with Roboze 3D printing

Roboze Additive Manufacturing can provide metal replacement solutions for swing check valves trim.

Roboze 3D printing with high-performance polymers can provide cost and lead time savings. Additive manufacturing can also be used to create complex geometries with high precision, reducing material waste and production time. However, it is crucial to meet ISO, API, and other relevant standards for industrial additive manufacturing to ensure the reliability and safety of the products. Roboze closely works with experienced valve repair services companies with guaranteed quality and warranty, helping customers worldwide maintain optimal valve performance through certified partners.

Download the document to find out the benefit of 3D printed check valves

Traditional methods have their limitations, they are still widely used for swing check valve trim production, especially in high-volume applications or when specific material properties are required. Roboze industrial 3D printing offers an alternative approach that can overcome some of these limitations, allowing for more design flexibility, reduced lead times and lower costs.

For end-users such as asset integrity and corrosion engineers, using Roboze super polymers for swing check valve trim repairs can provide numerous benefits.