Roboze, 3D printing solutions for the Aerospace and Defense sector

Why is Roboze 3D printing ideal for Aerospace and Defense production?

Everyday the Aerospace & Defense sector faces dilemmas related to reducing the weight of components to optimize performances, plan production and reduce the amount of CO2 emissions in the air.

By analyzing these topics individually, it was possible to identify the advantages that Roboze 3D printing can bring to the sector, managing to satisfy every single need.

Implementing a Roboze 3D printer or organizing production with the support of the 3D Parts network can generate important competitive advantages for Aerospace and Defense companies.

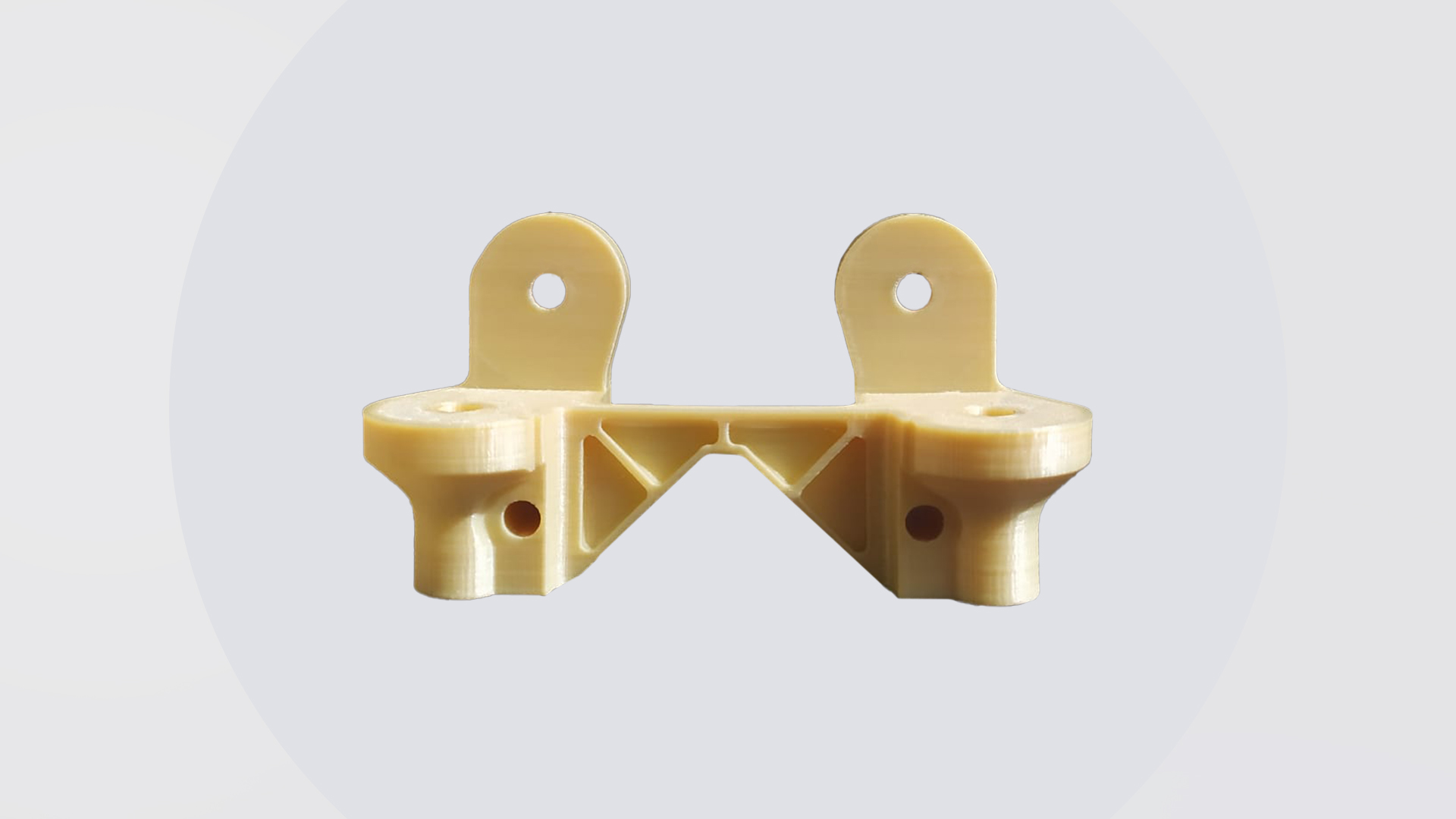

In fact, Roboze 3D printing solutions allow to accelerate the lifecycle of products in this sector thanks to the possibility of producing functional prototypes and finished parts with super polymers and composite materials instead of metal parts and with a patented technology capable to guarantee repeatability and process control over time.

Roboze composites have much lower densities than light metal alloys (halved on average), while ensuring excellent specific performance.

Furthermore, the high precision of Roboze systems can increase the degree of complexity of the parts for the benefit of greater performance since the design stage. It is possible, in fact, to produce parts with complex geometries with a reduced structure which on the one hand entails a further reduction in the weight of the printed part and on the other hand less waste of material with the consequent effect of reducing fuel and therefore emissions in the atmosphere.

Why does planning facilitate production?

The possibility to plan production is a very important variable within a business context. For this reason, the Aerospace and Defense sector finds in 3D printing a valid solution for manufacturing processes of certified and high performance parts.

By implementing Roboze 3D printers in your processes or relying on the consultancy and production of parts offered by the 3D Parts network, it is now possible to program, track and certify every single part, with Just in Time and On Demand productions.

The result? Dematerialization of warehouses, reduced or even eliminated costs, spare parts immediately available on site and no delays associated with external supplies.

The competitive advantage offered by Roboze is simple: a solution for the rapid supply of end use parts, individual consultancy and constant support, to ensure high performance, personalization a maximum satisfaction.

Contact one of our consultants for further information: info@roboze.com

Get ready to print strong like metal, on demand!

-

#PrintStrongLikeMetal #OnDemand