Reducing transportation costs with Roboze advanced manufacturing

The impact of transportation on the Supply Chain

From raw material handling to the distribution of finished products, traditional logistics is expensive, complex, and prone to delays and disruptions. Rising energy costs and increasingly stringent environmental regulations add to these challenges.

In a landscape where global supply chains are under pressure, adopting advanced manufacturing technologies presents a strategic alternative: distributed manufacturing, a model that significantly reduces dependency on transportation.

Distributed Manufacturing: the New Industrial Paradigm

Distributed manufacturing is an innovative approach that challenges the traditional centralized supply chain model. Instead of concentrating production in a few large facilities and distributing finished products worldwide, distributed manufacturing enables the production of components and products directly where they are needed. This transformation is made possible by Roboze’s advanced manufacturing technologies.

How does Distributed Manufacturing work?

The model is based on three key pillars:

1. Component Digitalization

Components are converted into digital files containing all the technical specifications required for production (geometries, printing parameters, materials). These files can be stored in a digital warehouse and instantly sent to any facility equipped with Roboze technology.

2. Localized Production

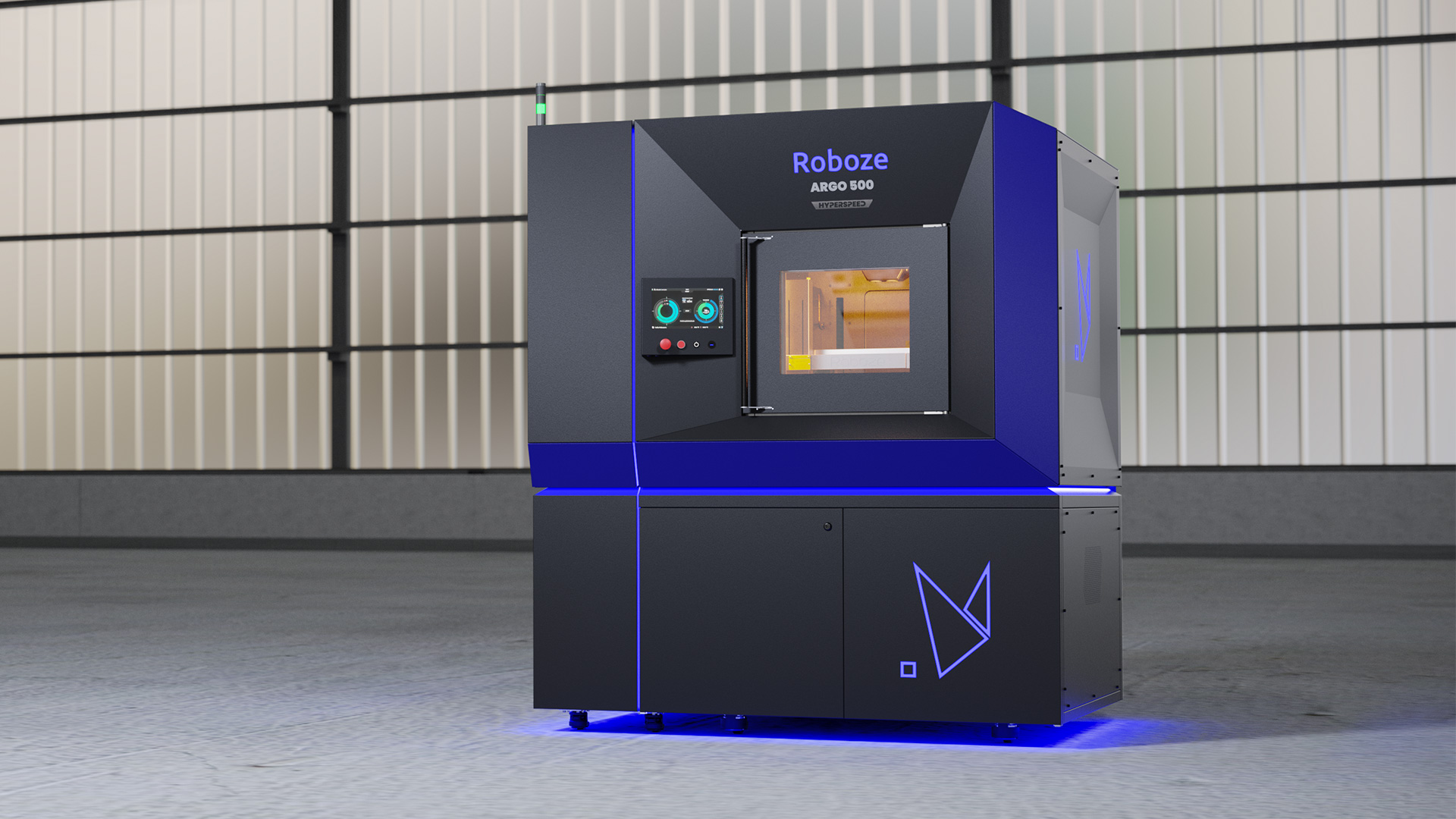

With solutions like ARGO 500 HYPERSPEED and ARGO 1000 HYPERMELT, components can be printed directly at the point of use, eliminating the need for physical transportation between facilities or countries. This drastically reduces logistics costs and accelerates production timelines.

3. Standardized Quality

Roboze technology ensures that every component produced, regardless of location, meets the same high-quality standards required by regulated industries.

Localizing production, combined with the use of high-performance materials, is the key to a more efficient supply chain. Solutions like Carbon PEEK and Carbon PA PRO, paired with the precision of Roboze technologies, enable the production of industry-compliant components without the need for centralized manufacturing.

Sustainability: an additional competitive advantage

Reducing transportation costs is not just an economic benefit, it’s an environmental one. Local production with Roboze solutions significantly lowers logistics-related emissions, contributing to a more sustainable supply chain. In an era where sustainability is a critical requirement for many industries, this advantage further strengthens competitiveness.

Strategic support for Supply Chain transformation

Roboze provides more than just technology—it partners with companies to transition towards more efficient and resilient production models. Through knowledge transfer and process optimization, we support customers in implementing distributed manufacturing, delivering scalable and measurable results.

Optimize your supply chain with Roboze. Contact us for a personalized consultation and discover how to reduce logistics costs, improve flexibility, and build a more sustainable future.