Smart factories: the new paradigm of Digital Manufacturing

From Traditional Production to Digital Manufacturing

The manufacturing industry has traditionally relied on a centralized production model, with large-scale factories concentrated in specific geographical areas. While this approach has provided efficiency through economies of scale, it has also revealed significant limitations in addressing today’s market challenges:

• Rigidity and long production lead times: The movement of raw materials and semi-finished goods between global facilities results in high costs and extended delivery times.

• Vulnerable supply chain: Global events such as pandemics, trade wars, and logistics crises have exposed the fragility of traditional supply chains.

• Limited customization: Centralized production struggles to accommodate rapid and cost-effective customization requests.

• Environmental sustainability: Long-distance transportation of goods increases environmental impact and resource consumption.

Technological innovation has introduced an alternative paradigm: digital manufacturing and smart factories, which represent the natural evolution to overcome these challenges.

The Smart Factory Model and the role of Digital Manufacturing

Smart factories are highly automated, connected, and digitized production facilities designed to operate with maximum efficiency through the integration of advanced technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), additive manufacturing, and machine learning.

In this context, digital manufacturing plays a central role, transforming how industrial components are designed, produced, and distributed. This transformation enhances the adaptability of production to demand fluctuations, eliminating the need for complex plant reconfigurations.

The integration of automated systems allows interconnected machinery to monitor and optimize production processes in real time, improving overall efficiency. As a result, supply chain management becomes more resilient, reducing dependency on external suppliers and enabling localized production of parts and components, ensuring uninterrupted operational continuity.

Digitalization also enables constant and detailed quality control, minimizing waste and enhancing production effectiveness. Finally, on-demand production allows companies to respond rapidly to market needs, eliminating the necessity for large inventories and accelerating delivery times.

The Roboze Advanced Manufacturing Model: from Centralized Production to Distributed Smart factories

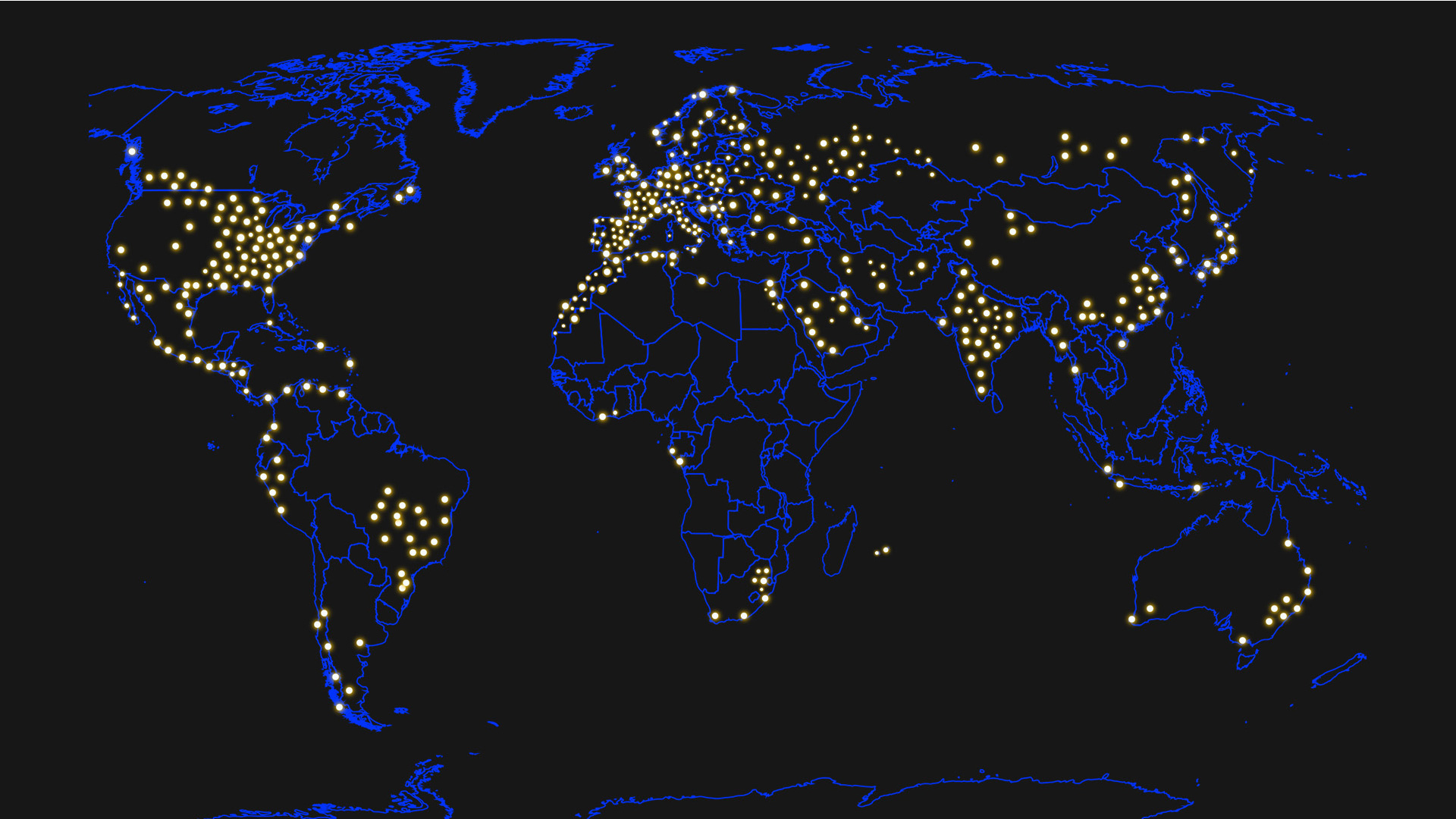

The concept of digital manufacturing is fully realized in the Roboze Advanced Manufacturing model, which establishes an ecosystem of distributed Smart factories equipped with Roboze technology for the advanced production of industrial components using non-metallic materials.

Key Advantages of the Roboze Model:

1. Localized Production, Global Impact

Strategically positioned Smart factories bring production closer to end-use locations, drastically reducing logistics costs and CO₂ emissions associated with international transport.

2. Additive Manufacturing for Industrial Production

Roboze technology enables the production of high-performance components using super polymers and composite materials, offering mechanical, chemical, and thermal resistance comparable to metals while significantly reducing weight.

3. Resilient and Decentralized Supply Chain

Companies no longer need to rely on distant suppliers for critical parts. Through our distributed model, each Smart factory can produce components on demand, mitigating supply chain disruption risks.

4. Customization and On-Demand Production

Customers gain access to customized, just-in-time production, eliminating the need for bulky and costly storage.

5. Digitalization and Total Process Control

Centralized data management, combined with remote monitoring of Smart factories, ensures continuous quality control and process optimization.

The adoption of Smart factories and digital manufacturing is redefining the industrial sector, making it more efficient, sustainable, and resilient. The Roboze Advanced Manufacturing model represents a natural evolution in this direction, empowering companies to produce critical components with a shorter, more agile, and robust supply chain.

Distributed Smart factories worldwide, equipped with our technology, are at the heart of this transformation. By leveraging additive manufacturing and digitalization, Roboze is accelerating the transition towards modern industrial production. Discover how our digital manufacturing model can support your company in the future of production. Contact us!