Optimized Small Batch Production with Roboze 3D Parts

Small batch production is becoming a key trend for modern manufacturing companies, particularly in the U.S. market. In an increasingly fast-paced environment, where demand for customization, high-quality parts, and speed are paramount, the ability to produce small, tailored quantities can define a product's success. Roboze 3D Parts stands out as an innovative solution for custom additive manufacturing, providing the flexibility industries need to tackle today’s production challenges.

The Importance of Small Batch Production in Manufacturing

Traditionally, small batch production has been expensive and inefficient due to high setup costs, long lead time, and manufacturing processes designed for mass production. These methods often fail to meet growing demands for on-demand production of custom parts while maintaining economic efficiency. As the need for more personalized and high-performance components rises, manufacturers must find smarter ways to deliver small batches without sacrificing profitability.

This is where industrial 3D printing becomes a game-changer. With Roboze 3D Parts, companies can drastically reduce production times and costs for small batches while maintaining exceptional quality. This capability enables on-demand spare parts production and functional component manufacturing with minimal lead time.

How Roboze’s Global Network Enhances Small Batch Production

What happens when advanced 3D printing technology is made accessible globally through a certified distributed network? The answer is Roboze 3D Parts, a platform that leverages a global network of partners to provide scalable, localized 3D printing services. This structure amplifies the benefits of 3D printing by enabling companies to expand their small batch production capabilities while reducing costs and time to market.

The Roboze 3D Parts Network: A Global Support System for Manufacturers

A key advantage of Roboze 3D Parts is its global network of partners, all utilizing cutting-edge 3D printing technology. This distributed model allows manufacturers to scale production locally, reducing delivery times and cutting logistical costs. It also ensures consistent high-quality production for both rapid prototyping and final components, regardless of geographic location.

The network’s strength lies in its ability to provide localized production, enabling businesses to meet regional market demands with greater agility. This localized production model significantly reduces the environmental impact associated with international shipping, making it a more sustainable solution for industries that require fast, efficient manufacturing.

Advantages of Small Batch Production with Roboze 3D Parts

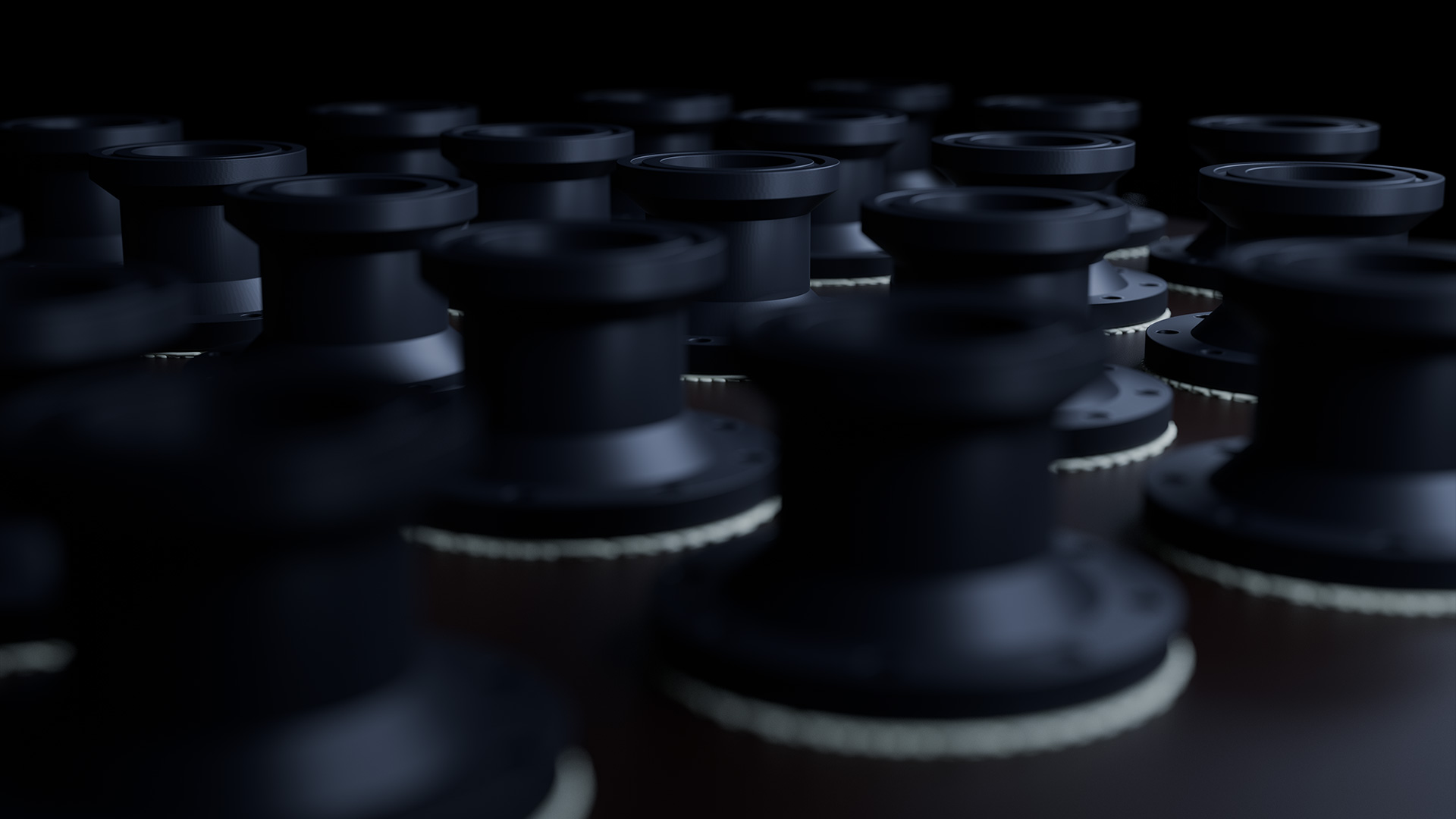

Roboze 3D Parts offers tailor-made solutions for small batch production using advanced materials like PEEK and Carbon PEEK, ideal for high-demand applications in sectors such as automotive, aerospace, and energy.

Key benefits of Roboze technology for small batch production include:

1. Reduced Setup Costs: 3D printing eliminates the need for expensive setup and tooling, making it economically viable for small batches.

2. Design Flexibility: With custom additive manufacturing, companies can produce highly complex geometries that would be impossible or too costly using traditional methods, speeding up product development.

3. Speed and Responsiveness: Rapid prototyping enables businesses to quickly validate new designs and reduce product development cycles.

The Roboze 3D Parts network amplifies these advantages, offering the scalability required for expanding small batch production efficiently while ensuring consistent quality worldwide.

Roboze 3D Parts: A New Era for Small Batch Manufacturing

With its unique combination of scalability, localization, and customized 3D printing, Roboze 3D Parts is a strategic asset for manufacturing companies looking to streamline small batch production. Our global network of partners using Roboze technology enables rapid, flexible responses to market demands, ensuring cost-effective, sustainable manufacturing closer to the customer.

The ability to produce high-performance custom components in reduced timeframes provides a significant competitive advantage. This agility helps businesses stay ahead of market trends while meeting specific production needs. The advanced materials used in Roboze 3D printing, such as PEEK and Carbon PEEK, ensure that the parts produced can withstand the most demanding operational environments.

Contact our experts today to discover how Roboze 3D Parts, through its global network, can support your company in small batch production, improving efficiency, reducing costs, and accelerating time-to-market. Send us your project, and together we can assess feasibility and the best production solutions for your needs.