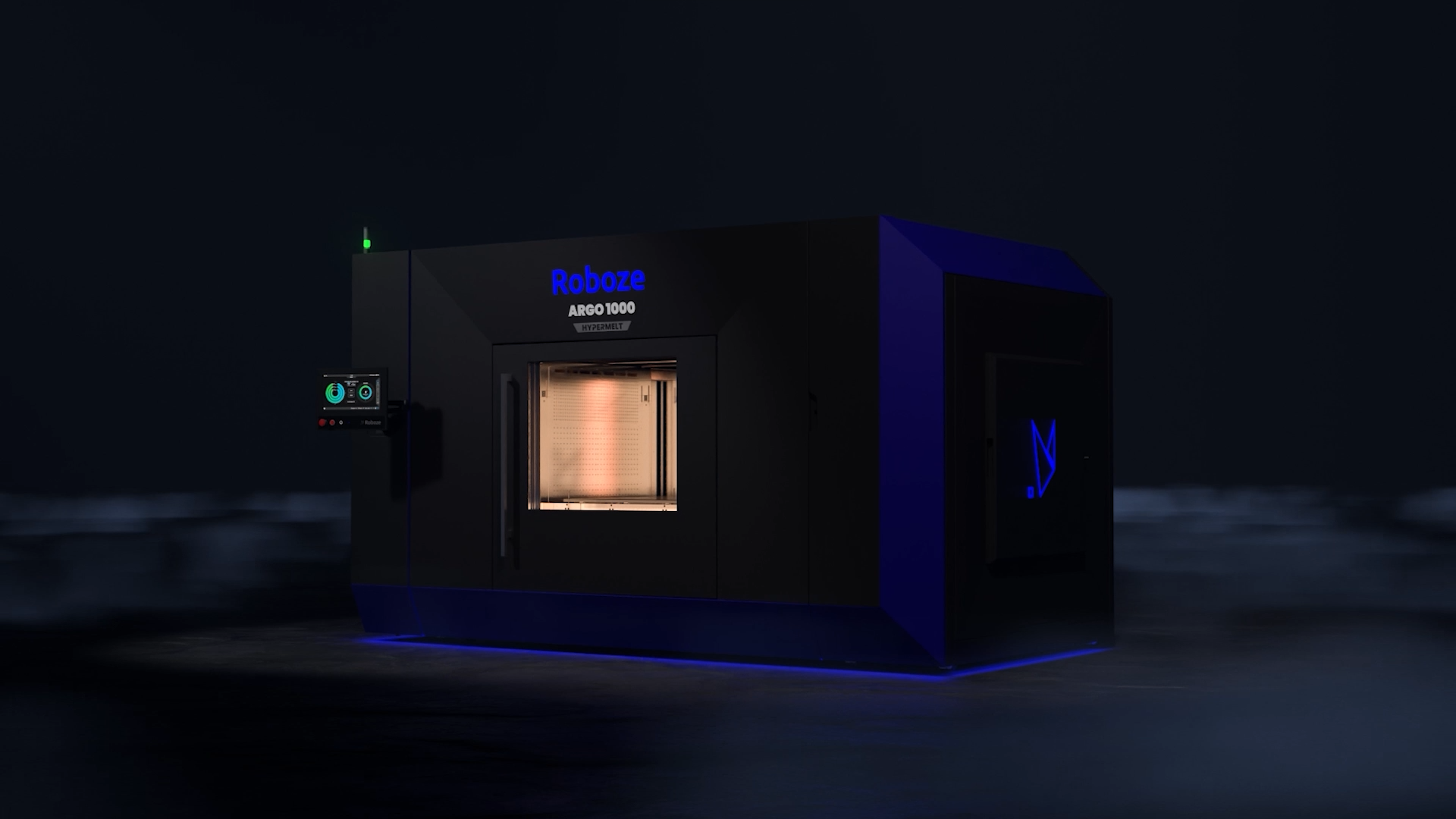

ARGO 1000 HYPERMELT: the evolution of large format 3D printing

3D printing has reached new heights with the introduction of the ARGO 1000 HYPERMELT, the largest 3D printer equipped with a 180°C heated chamber and pellet technology. This solution promises to revolutionize additive manufacturing of large-format parts with super polymers, composites and engineering materials.

ARGO 1000 HYPERMELT is the result of a precise vision of the future of manufacturing, in-depth technological work and the challenge of engineering complexity. We delve into it in the dedicated keynote with those who commit their energy every day to accelerating the adoption of additive manufacturing and the digital transformation of production processes around the world

The keynote opens with Alessio Lorusso, Founder and CEO of Roboze. With his vision, Lorusso outlined the future of production through 3D printing, highlighting how the HYPERMELT technology on ARGO 1000 opens up new application opportunities in sectors such as aerospace, energy and mobility.

Simone Cuscito, Chief Research and Development Officer of Roboze, then delves into the technological elements of the solution, with a particular focus on the importance of research and development, underlining the challenges overcome and the objectives achieved.

Finally, Federico Iozzelli, PhD, CTO of Roboze, offers an overview of how the implementation of ARGO 1000 HYPERMELT in production processes can help producers meet specific manufacturing challenges. Through a scientific perspective, Iozzelli explains how to overcome the complexities related to advanced materials while ensuring tangible benefits in the production phases. ARGO 1000 HYPERMELT is a system that offers not only a solution to current needs but also a competitive advantage in the creation of high quality large format parts.

To further explore the ARGO 1000 HYPERMELT solution and understand how this innovation can transform your production of large format parts, we invite you to visit the dedicated page and contact our experts.

Take part in the evolution of production! If not now, when?