3D Printing Materials, composites and polymers: definitions

3D printing materials: overview

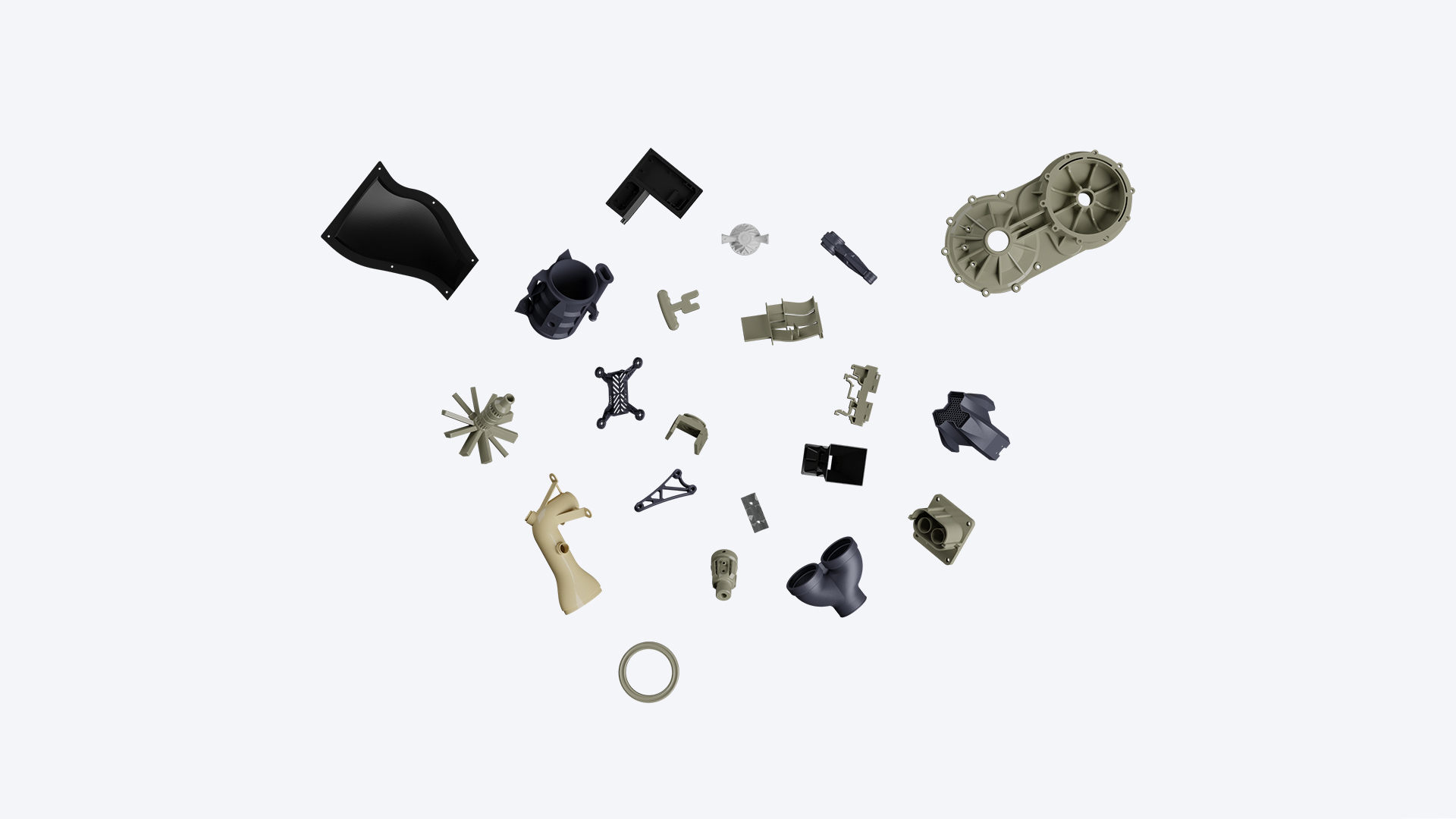

Advances in high-performance composites and polymers for 3D printing have paved the way for new frontiers in rapid prototyping and additive manufacturing.

Thanks to 3D printing materials, additive manufacturing today also offers large-scale solutions with extraordinary mechanical, chemical and thermal performances. Whether basic thermoplastics, super polymers such as PEEK, PEKK and ULTEM, or carbon fiber reinforced composites, each class of materials unlocks new design and application potential. But what are the materials for 3D printing?

• Thermoplastic Materials: thermoplastic materials such as polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS) are the most common materials for 3D printing. PLA is biodegradable, has a low melting temperature and is easy to print, but it is fragile. ABS is more durable and flexible, with a higher melting temperature and amenable to a variety of post-production techniques, such as sanding, painting and gluing;

• Composite Materials: composite materials, such as carbon fiber-reinforced polymer (CFRP) and glass fiber-reinforced polymer (GFRP), offer greater strength and rigidity than thermoplastics. CFRP, in particular, has superior mechanical properties and the carbon fibers can also influence other properties of the neat polymer. These materials are suitable for applications requiring high performance, such as in the aerospace industry;

• High performance polymers: super polymers, such as polyether ether ketone (PEEK), polyether ketone ketone (PEKK), and polyetherimide (PEI – ULTEM), offer unique combinations of properties such as chemical resistance and high temperature resistance. They are ideal for critical applications in sectors such as Oil & Gas and automotive. 3D printing these materials is not trivial and requires specially designed technological ecosystems, but, when there are the requirements for printing these advanced materials, it is possible to obtain intricate geometries that are difficult to achieve with other processes. In this article we have explained the difference between PEEK and PEKK, useful before describing the characteristics of the super polymers PEEK and ULTEM.

High performance 3D printing materials: PEEK and ULTEM

Advanced materials like PEEK and ULTEM offer superior performance for demanding applications. Here are their main features:

• Excellent mechanical properties, high temperature resistance: PEEK and ULTEM are known for their chemical and thermal resistance and their self-extinguishing properties. Both materials maintain rigidity and strength at high temperatures. Their chemical resistance makes them suitable for aggressive environments;

• Lightness: the lightness of PEEK and ULTEM 3D printing materials represents a critical and distinctive element that makes them particularly suitable for a wide range of applications, especially in sectors where weight plays a key role, such as aerospace and motorsport. Where performance and efficiency are of primary importance, the choice of lightweight materials like PEEK and ULTEM represents a strategic decision that favors both technical performance and operational efficiency;

• Workability: the workability of PEEK and ULTEM requires industrial quality 3D printers capable of reaching high temperatures. Adhesion between layers and thermal deformation can be problematic, so it is important to use professional solutions, especially if working in the additive manufacturing field. However, with the specific equipment and skills these advanced materials offer exceptional performance in environments requiring thermal and mechanical resistance.

The most widely used 3D printing technologies with high performance materials

• FFF technology with high performance materials

Fused Filament Fabrication (FFF) technology has revolutionized the 3D printing landscape, making the production of prototypes and functional parts accessible. In recent FFF developments, there has been an increasing adoption of high-performance materials, significantly extending the application possibilities of 3D printing. Materials such as PEEK and ULTEM have become protagonists in this context, bringing FFF to new levels of versatility and robustness. The ability to use high-performance materials in a fused filament deposition 3D printing technology opens the way to a wide range of applications in critical industries such as aerospace, automotive and industrial manufacturing.

FFF technology with high-performance materials is suitable for the production of complex components, such as vehicle aerodynamic parts and cooling system components, which require exceptional wear resistance, rigidity and, sometimes, thermal properties. Additionally, it allows for more complex and customized design, allowing designers to take full advantage of the unique characteristics of materials such as PEEK and ULTEM. This synergy between FFF technology and advanced materials opens new horizons in the field of customized manufacturing, promoting innovation and speed in the development of prototypes and final products.

• Large-scale printing with FGF and advanced materials

Large-scale printing with Fused Granular Fabrication (FGF) technology and advanced materials is revolutionizing the additive manufacturing landscape, enabling the creation of large-scale components with high performance. This methodology is characterized by the use of thermoplastic material granules, allowing efficient and sustainable production on a larger scale. Advanced materials such as glass fiber reinforced polypropylene (PPGF) and polyamide (PA) are emerging as key players in this context, offering a combination of strength, flexibility and durability.

When working with advanced materials, given their high-performance characteristics, the available solutions become limited. One of these is the HYPERMELT technology developed by Roboze, which is among the first to offer the possibility of printing materials such as PEKK and ULTEM. The ability to use advanced materials allows the production of components that meet rigorous requirements for performance, resistance to atmospheric agents and durability. The flexibility of this technology allows production processes to be easily adapted to the specific needs of the project, offering a rapid response to market demands, offering an optimal balance between size, performance and sustainability.

Industrial applications with high-performance materials for 3D printing

The adoption of high-performance materials is paving the way for new industrial applications of 3D printing. Thanks to their versatility and strength, they are ideal for the production of durable components in sectors such as aerospace, automotive and energy.

• Aerospace applications: aerospace applications are experiencing a significant transformation thanks to the introduction of advanced 3D printing materials. The use of 3D printing technologies with high-performance materials has opened up new possibilities in the design and manufacturing of aerospace components. The lightness, strength and customization capacity offered by these materials play a crucial role in reducing the overall weight of aeronautical structures, thus contributing to improving the efficiency of space vehicles. Advanced 3D printing materials enable the creation of complex, geometrically optimized components, improving the shape of parts to ensure maximum aerodynamic efficiency. This custom design capability not only reduces overall vehicle weight, but can also improve overall performance, from structural strength to temperature management. Additionally, 3D printing offers faster production times and greater flexibility in prototyping and modifying designs, critical elements in aerospace projects that require rapid responses to engineering challenges. The application of advanced 3D printing materials in aerospace not only offers benefits in terms of performance and efficiency, but also contributes to greater sustainability through the reduction of production waste and the possibility of recycling materials;

• Automotive applications: the introduction of advanced materials for 3D printing has also influenced the automotive sector, offering innovative opportunities in the design and production of key components. As with aerospace, the lightness and mechanical strength of materials such as carbon fiber reinforced polymers allow the creation of lighter components, without compromising structural integrity. This is especially crucial in the automotive sector, where weight reduction directly translates into improvements in performance, fuel efficiency and handling. The adoption of 3D printing using advanced materials in the automotive sector also has a significant impact on manufacturing, especially when it comes to supporting production lines. One example is the creation of molds for carbon fiber lamination, a critical process in the production of lightweight, high-performance components for the automotive sector. 3D printing is emerging as a key technology in the production of prototypes, spare parts and customized components, heralding a new era in vehicle design and manufacturing with an increasing focus on lightweight, customization and overall efficiency.

• Applications in the energy sector: applications in the energy sector are significantly benefiting from the use of advanced materials for 3D printing, with a particular focus on corrosion resistance. An eloquent example of this application is found in the production of pump impellers used in different fields, from purification systems to wastewater management systems, from offshore to downstream applications, where resistance to corrosive agents is fundamental to ensure long-lasting and efficient performance. The corrosion resistance of these advanced materials is of particular importance in marine environments and in places characterized by high levels of oils and acids. Impellers made from corrosion-resistant materials can maintain their efficiency over time, reducing the need for frequent maintenance and increasing the overall operating life of energy systems. Furthermore, 3D printing enables the customized production of components, tailored to the specific needs of each energy application, representing a significant step towards increasing the reliability and sustainability of energy infrastructure.

In conclusion, 3D printing is booming and advances in the development of new materials for 3D printing are fueling technological innovation. As advanced 3D printing materials become workable with additive manufacturing methods, possible applications will expand in ways that are difficult to imagine today. From aerospace to industrial manufacturing, advanced materials are the key to unlocking the potential of 3D printing and transforming design and manufacturing processes. If we can take full advantage of these innovative materials, the future of additive manufacturing will be bright!

For further information, get in touch with Roboze.