The electric car industry and electric mobility are experiencing significant growth worldwide. There are several reasons for this rapid increase in the popularity of electric cars and the adoption of electric mobility. The best known include goals of environmental sustainability and reduced dependence on fossil fuel sources resulting in mitigation of the effects of fuel price fluctuations.

With technological advancement, continued government support and increased environmental awareness, the adoption of electric cars is expected to continue to accelerate in the years to come.Growth inevitably also involves evolution in terms of innovation as new methods and ideas must necessarily be supported by specific technologies in response to new needs.

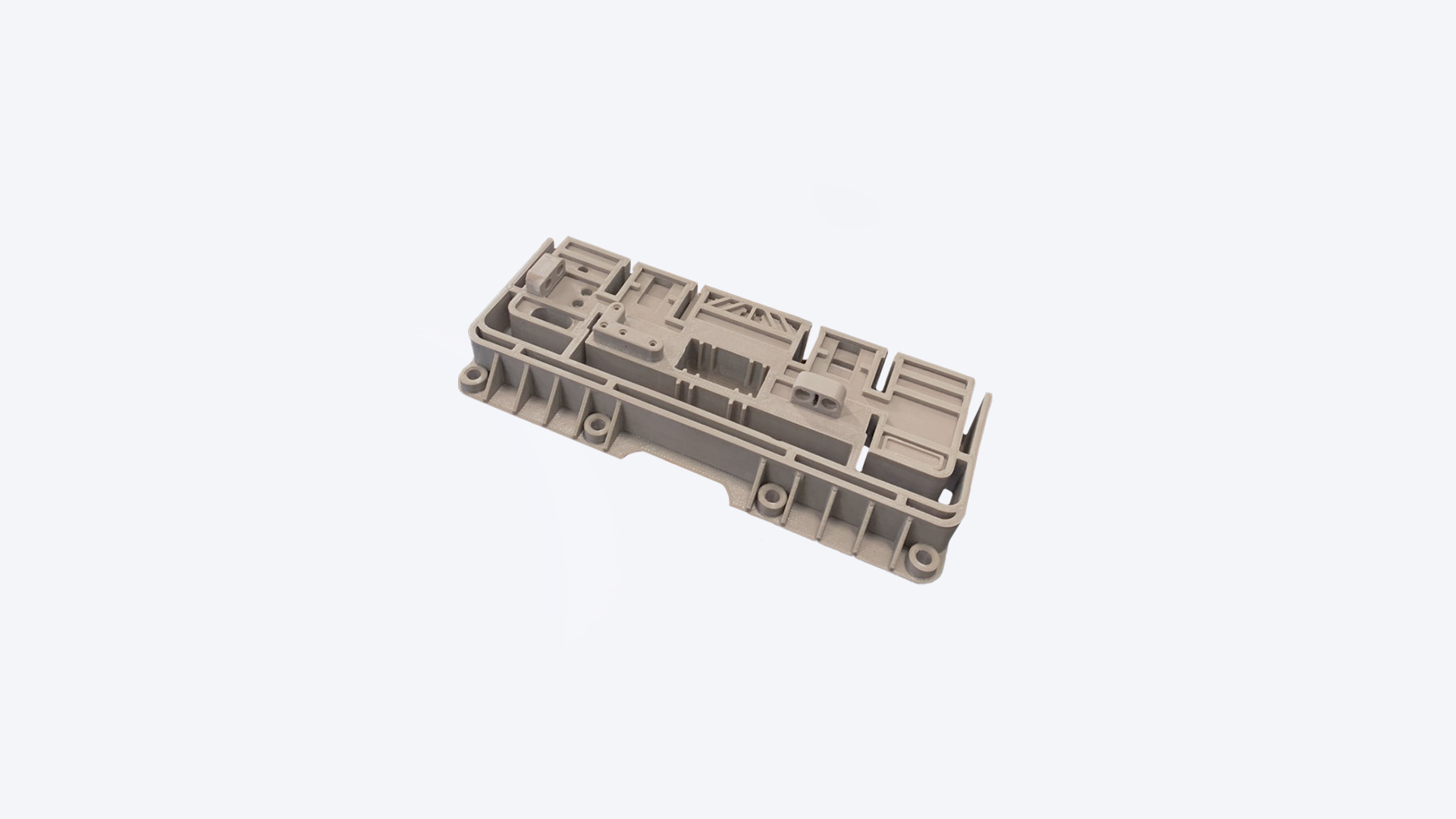

The proposed application case of the busbar support is a great example to describe how 3D printing today is increasingly becoming a critical choice in various industrial applications.

Busbars are generally used to distribute energy from one point to another. In electric vehicles, its function is to transfer energy from the battery pack to the electric motor. They require strong and thermally stable supports to maintain their position and prevent sagging or deformation.

While traditional manufacturing methods are well established in the production of busbar supports, advanced manufacturing technologies like Roboze 3D printing offer several benefits that can help overcome some of the limitations of traditional methods.

See how one of our customers, producing PEEK busbar supports in-house with the ARGO 500 solution, optimized the production of these parts by customizing them according to specific needs and use without additional investments, and without the need of adapting each production according to the geometry.