Benefits of industrial 3D printing for ultrasonic cleaning

Industrial ultrasonic cleaning is an effective method to clean metal parts, especially those with complex geometries, mainly when they have been in contact with oil, grease, rust or small particles: for instance chip after machining steps. Part supports for industrial ultrasonic cleaners can include a variety of holders or fixtures that are designed to securely hold the parts in place during the cleaning process.

Given the small production volumes of these parts, which inevitably affect production and logistics costs, internalizing the process using an industrial 3D printing solution brings substantial advantages in terms of logistics, costs and washing efficiency.

Reduce production costs and times with FLEX-TPU 3D printing

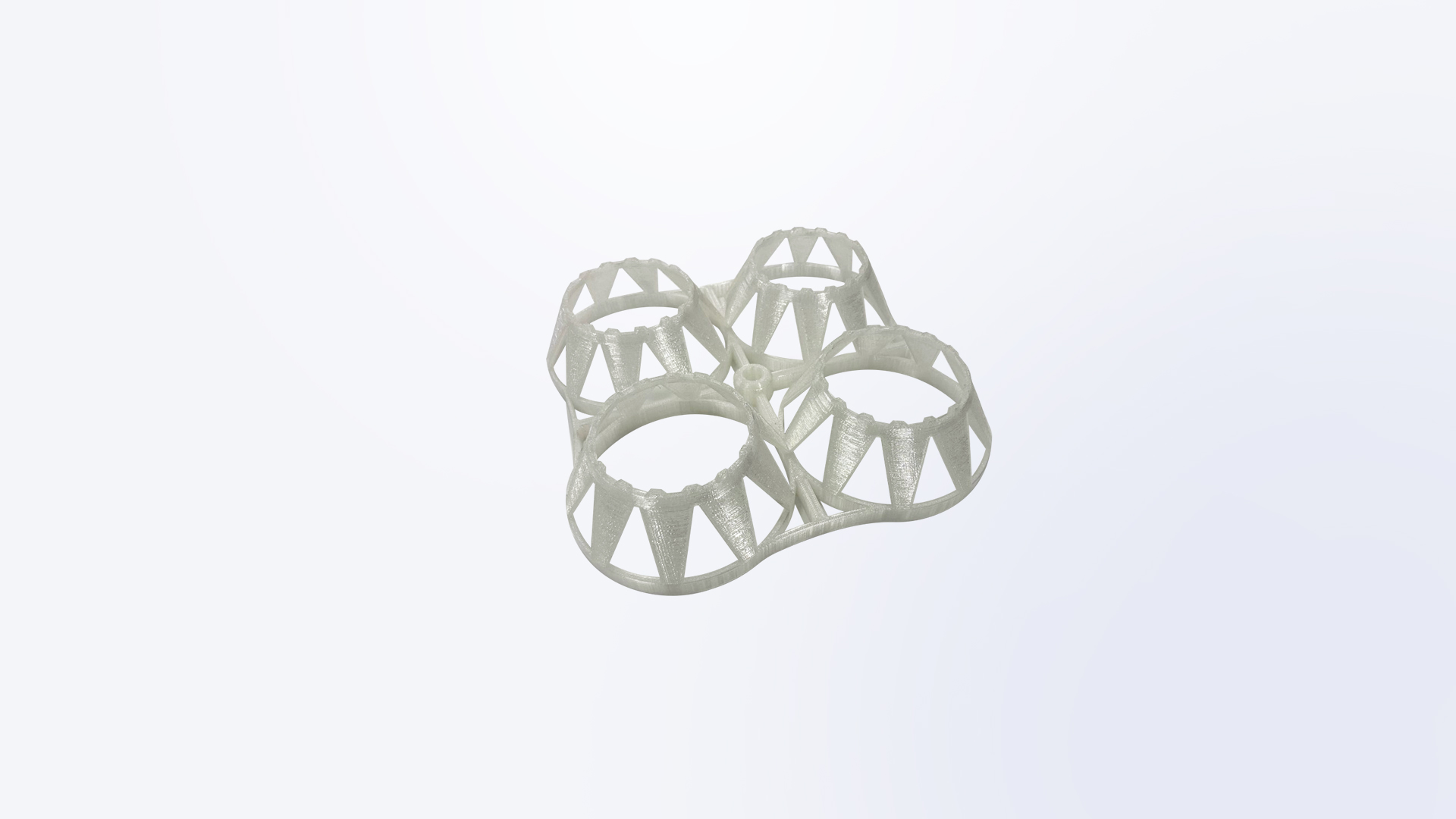

A customer active in the automotive industry has made the process more efficient with customized geometries that improve wettability and drying, thanks to supports 3D printed with Roboze PLUS PRO for ultrasonic industrial cleaning. These supports were printed in FLEX-TPU, a polymer based on thermoplastic polyurethane, which provides the best combination of temperature, chemical resistance, and low cost.

FLEX-TPU 3D printed supports are manufactured in short time and with a low cost, requiring minimum effort for customization thanks to additive manufacturing design freedom.

Download the document to learn more.