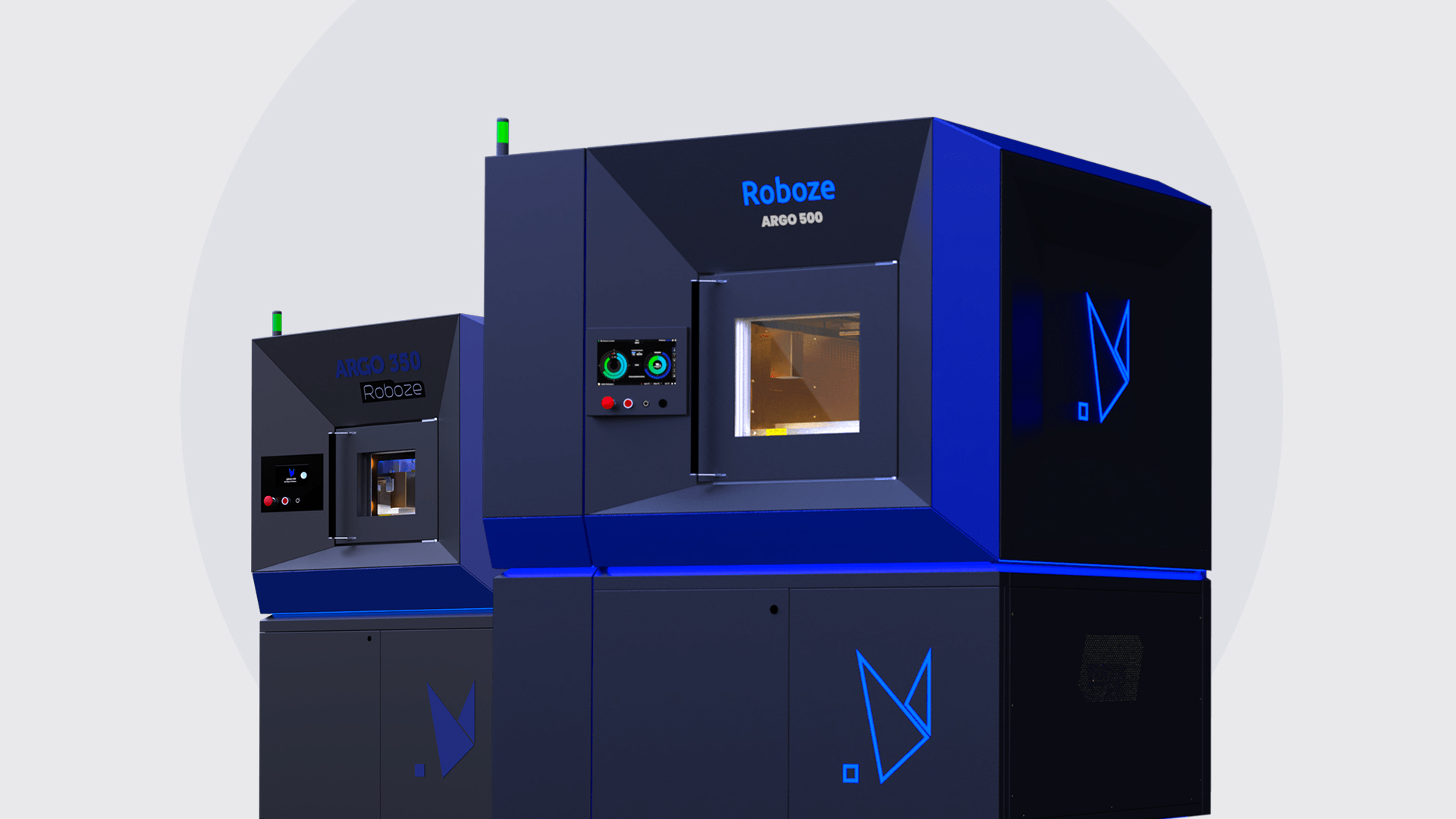

Roboze Production Series: flexible systems of high performance additive manufacturing

Roboze ARGO 3D printers: what are the advantages?

The 3D printers of the Production series, ARGO 350 and ARGO 500, already chosen by the biggest global players in the Automotive, Aeronautics, Space and Defense sectors, are advanced additive manufacturing systems developed to streamline and make production processes flexible with a reduction of time and costs up to 90% compared to traditional methods, allowing to optimize the logistic chain with the 3D printing of large-scale finished parts and components using the most performing high temperature composite materials and super polymers of the entire industry.

The presence of the heated chamber up to 180°C, combined with a thermal control system and smart sensors, in addition to accelerating the printing processes and therefore increasing the productivity of the companies, allow a repeatable and high performance processing using super polymers such as PEEK, Carbon PEEK and Carbon PA which are able to replace those metals used for traditional manufacturing ensuring excellent chemical, thermal and mechanical resistance.

Thanks to its characteristics, the Production series can transform traditional manufacturing, creating On Demand and Just in Time parts, concretely revolutionizing the traditional production process through additive manufacturing. For more information about all the technical aspects that characterize the Roboze ARGO series, register for the Webinar dedicated to Roboze technology that will be held on May 21st: JOIN THE WEBINAR

#PrintStrongLikeMetal