Reducing Operational Costs with the Digital Supply Chain

Reimagining Supply Chains to eliminate hidden costs

Traditional supply chains often come with rigidity that hampers business agility. Excess inventory, high waste rates, and long lead times not only increase expenses but also limit the ability to adapt to market changes. Financially, these inefficiencies reduce operating margins and inflate capital expenditures (CAPEX).

A common example is the hidden costs associated with global logistics—delivery delays, customs duties, and disruptions in international supply chains. Reducing dependency on external suppliers by internalizing critical processes with additive technologies can lead to substantial savings.

Advanced Manufacturing and strategic materials: the core of the digital Supply Chain

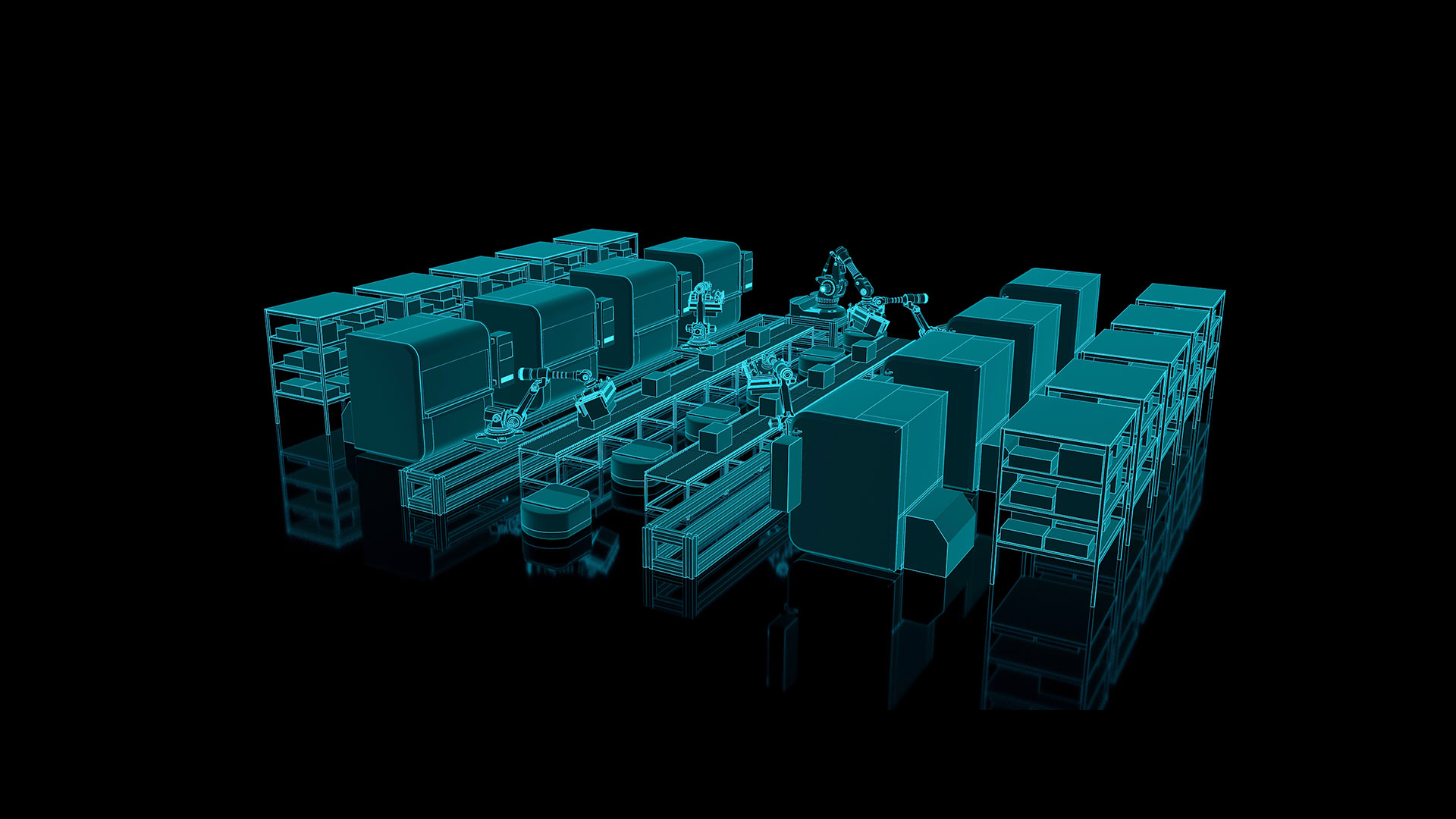

Advanced manufacturing is pivotal to supply chain transformation, leveraging additive manufacturing technologies and cutting-edge materials to enhance efficiency and cut costs. Roboze offers an integrated approach that not only enables in-house production but also connects businesses to a global network of distributed manufacturing centers, ensuring flexibility and proximity to end markets.

With systems like the ARGO 500 HYPERSPEED and ARGO 1000 HYPERMELT, companies can internalize key production processes, reducing reliance on external suppliers and improving supply chain control. For cases where in-house production isn’t practical, Roboze’s distributed network provides on-demand printing solutions worldwide, enabling fast delivery and efficient resource management.

A prime example is the ability to produce custom components on-demand, close to the point of use. This eliminates complex logistics and costly storage while fostering a streamlined, sustainable workflow. Digital project management further supports this vision by maintaining a “virtual warehouse” of CAD files, used only when needed, thereby minimizing waste and costs associated with physical inventory.

Roboze’s advanced materials play a crucial role in this transformation. Super polymers such as Carbon PEEK and Carbon PA PRO offer mechanical, thermal, and chemical resistance comparable to traditional metals, with the added benefits of being lighter and easier to process. This enables weight reduction in components, improved energy efficiency, and, in many cases, the elimination of costly processes like autoclave curing or heat treatment.

For example, in the energy sector, a client replaced metal components with advanced super polymers for high-pressure applications. This decision not only reduced production time by 40% but also lowered overall operational costs by decreasing maintenance needs and enhancing component durability.

This integrated approach, combining state-of-the-art technologies, innovative materials, and a distributed network, represents the new frontier of industrial production. Roboze delivers more than technological tools—it provides a strategic vision to optimize supply chains and empower businesses to maximize their production processes, no matter how complex.

Expertise that makes a difference

Digitizing the supply chain isn’t just about machines; it’s about transferring the expertise needed to use them effectively. Roboze supports companies at every stage of the process—from design to production to optimizing end applications. Through our know-how, we help partners integrate advanced solutions, reducing errors and boosting efficiency.

Reducing operational costs isn’t just a necessity; it’s a priority for building resilient supply chains. With Roboze, companies can transform their production, achieving results that enhance both efficiency and long-term economic sustainability.

Ready to discover how to optimize your supply chain with advanced solutions? Contact us for a consultation.