How 3D printing meets the needs of aircraft industry

The aviation industry is one of the most demanding in the world, exacting incredibly high standards and precisions from its materials and parts. One of the reasons is that a large part of the aviation industry is geared towards passenger transportation*. Therefore, only materials and parts that have been thoroughly tested can be used.

The aviation sector is in continuous evolution, always developing new parts and designs that result in more efficient aircraft. These new designs and parts are subjected to particularly rigorous and long-lasting testing campaigns before being certified for flight.

Testing of functional engines and prototypes is a key step in verifying that performances meet the standards required and can be done in several ways and with many different types of instruments. One of the most common is with test benches, also used in other industries like automotive, which provide highly accurate and realistic results.

The traditional manufacturing of custom testing components

When using test benches, it is often necessary to manufacture custom parts to ensure compatibility between the test subject and the test bench. These custom components can be anything from clamps to adapters to piping. It goes without saying that the parts need to be able to withstand the testing environment, otherwise they would be destroyed and invalidate the test results. Given the high requirements of the aerospace industry, this means only the highest quality materials can be used.

The custom parts should also be as easy as possible to manufacture so as to reduce the cost, since they are produced only in very small quantities. It is possible to acquire standardised parts but there are instances when a customised part is needed, for example when integrating several components into one to simplify and streamline the interface between the test bench and the part being tested.

Integration usually means geometrical complexity, though, and the manufacturing cost of parts is largely determined by this factor. So, parts such as adapters can be very expensive because they are not easy to manufacture using techniques such as CNC machining. In the end these custom parts often end up being a trade-off between complexity and cost, which might make them sub-optimal or cause the testing campaign to slow while waiting for their delivery.

Luckily, this is where Roboze 3D printing and high-performance materials come in.

PEKK and the 3D printer Roboze Plus PRO

Part of the polyaryletherketone (PAEK) family, PEKK is a high-performance thermo-polymer with exceptional qualities that include strong mechanical properties, high thermal resistance, and a wide chemical compatibility. These are key in withstanding the mechanical loads, vibrations, temperatures, and chemicals (e.g., oils and aircraft fuel) during testing, otherwise they would be destroyed in the process.

PEKK is also known for its incredibly good resistance to hydrolysis in hot water and steam, excellent FST (flame, smoke, toxicity) properties, and a V-0 UL94 flame resistance. This makes PEKK an excellent option for applications in extreme industries such as aviation, space, and energy and easily fulfils the first feature requirement discussed above.

But such a material is not very useful without the ability to manufacture parts out of it, especially if the cost needs to be contained. The PRO series 3D printers by Roboze are the best solution for high-complexity, low volume applications such as functional prototypes or parts for test benches thanks to its inherent design freedom and high accuracy. Adapters, jigs, and consolidation of several parts into one become immediate with this technology and since the cost of the customization stays the same irrespective of the quantity, it is ideal for small production batches.

Production of PEKK fuel manifold for aircrafts test bench

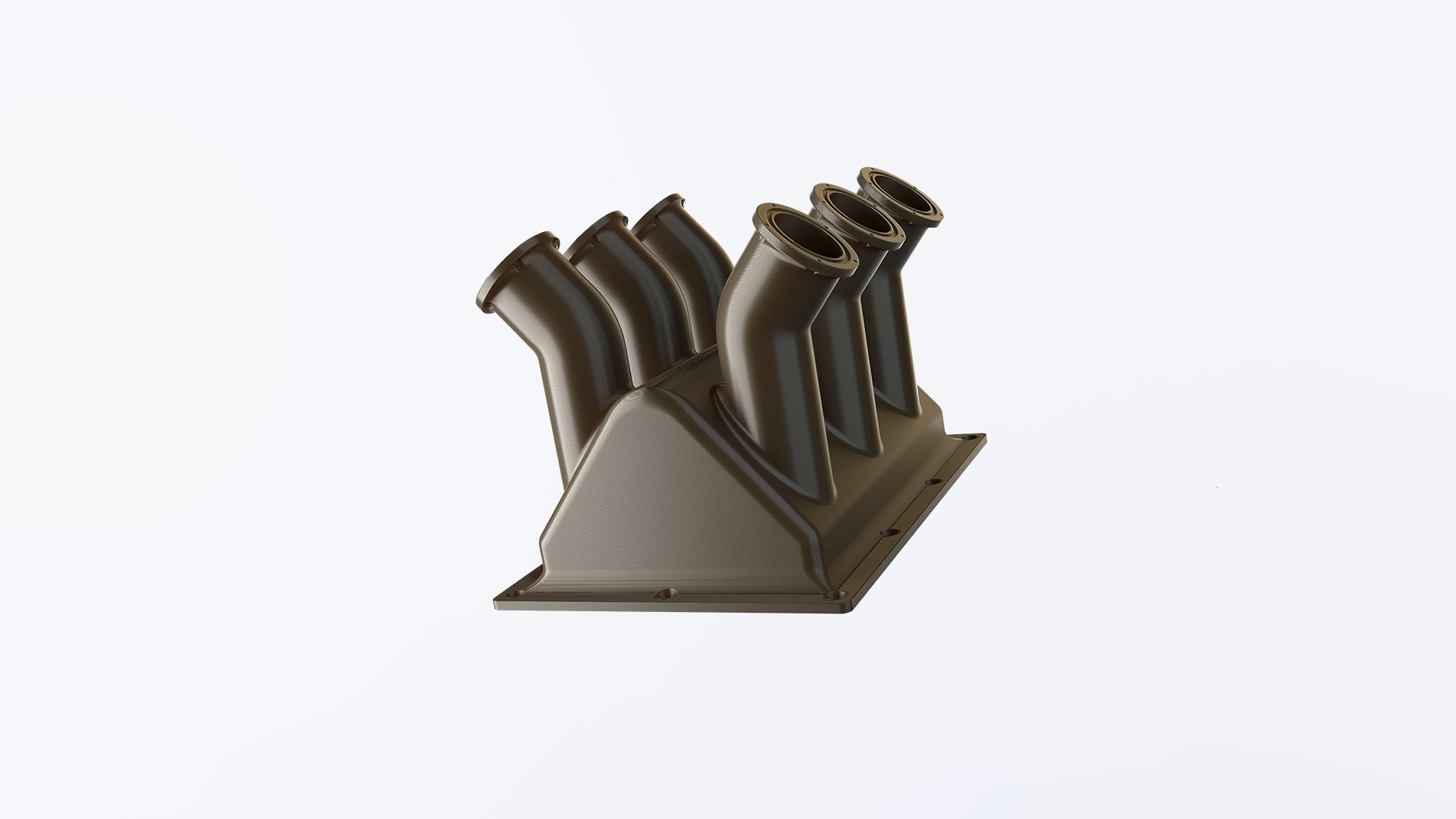

The combination of PEKK and the Roboze Plus PRO is ideal for the production of aircraft test bench parts such as the fuel manifold shown below.

As previously discussed, PEKK is a material that is well suited to use in the aerospace industry. The wide chemical resistance of PEKK means that engine oil and aircraft fuel do not run the risk of degrading parts made with this material. As well as having inherent robust mechanical properties, printed PEKK parts have a particularly strong inter-layer bond, so much so that complex piping and adapters for high pressure fluids can be easily manufactured. The layered nature of 3D printing also means that printed materials naturally absorb vibrations and don’t resonate easily.

Having a Roboze Plus PRO in-house allows the fabrication of a large variety of customised parts in a short time and at a low cost. The 3D printer occupies a small space compared to larger industrial printers, so is perfectly suited for research labs or workshops. The PRO series includes all the innovative elements brought to the market in recent years by Roboze: the best accuracy and repeatability on the market, ensuring only the highest quality 3D prints. The strength of the Roboze ecosystem lies in every single process step: from the preparation of materials and the automatic setting of the machines to the removal of the piece in the chamber. Everything is designed to offer a highly productive, repeatable, scalable and highly efficient solution.

Find out how you too can access these benefits and achieve a flexible and performance-oriented process. Contact us today!