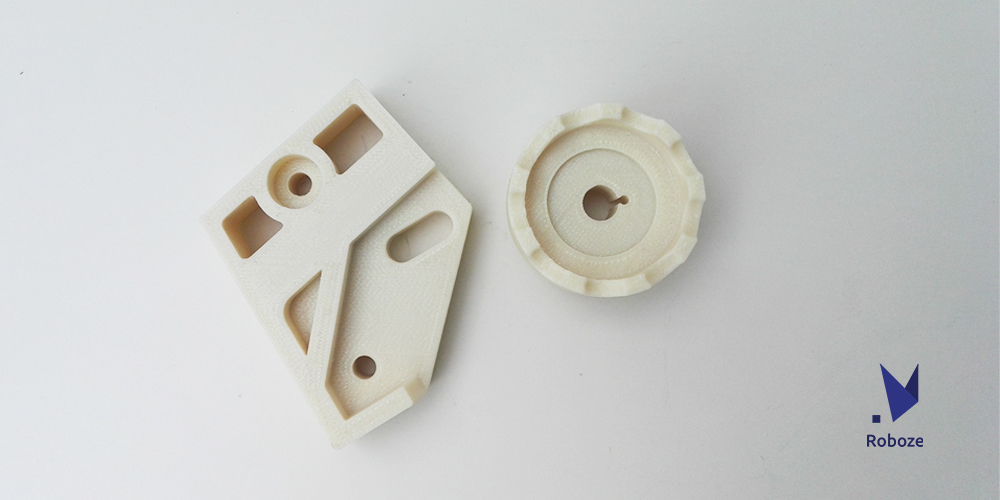

Nylon 6 is one of the most widely used techno-polymers among all commercially available nylons due to its good performance-cost ratio. Often used in the mechanical industry for the manufacturing of gears, bushings, cams, pulleys, wear-resistant guides, and in applications where good fluidity and wear resistance is required. Nylon 6 possesses a number of unique mechanical properties, such as good tensile strength, compression and fatigue, combined with low friction coefficient that make it abrasion-resistant and self-lubricating.

A disadvantage of Nylon 6 is the difficulty with automatic machining processes, as these processes demand trained operators, specific tools, and reduced processing speeds (to prevent material from overheating and part deformation that prolong production time.

The manufacturing of mechanical components in Nylon 6 with complex geometries with automatic machining requires a series of steps, manpower and planning of process parameters in order to attain optimal results.

FFF additive technology renders automatic machining’s labor-intensive processes obsolete.

Parts printed with Roboze Nylon 6 have all the mechanical and self-lubricating characteristics that make it the preferred choice in the mechanical industry, the same precision and performance without taking specific precautions for different stages of production.

The production time-cost advantage is clear: design freedom without the manpower, special tools, or lengthy process planning. Simply design the component, load the filament and print!