Metal Replacement 3D Printing, Roboze solutions that integrate into traditional production

Metal Replacement in the global market: why is it an advantage?

In recent years, the plastics industry has made great strides in developing super polymer and composite materials that allow the production of strong and light parts to replace metal. In addition, these parts have a broad resistance to chemical corrosion and excellent tribological behavior thanks to self-lubricating properties.

Today these polymers are revolutionizing various sectors: from aerospace to the transport sector, where lightness means better performance, to the chemical and energy industry, where a polymer capable of working in difficult environments and high temperatures can significantly reduce the need for maintenance.

According to the 2021 Global Metal Replacement Sales Market Report, the global metal replacement market was valued at $ 109 billion in 2020 and will reach $ 170 billion by the end of 2027, growing at a CAGR of 7.2% from 2022 to 2027.

More and more companies are looking to 3D printing associated with these materials as a valuable tool for complementing traditional manufacturing, producing small custom batches, and reducing cost and lead time for their customers.

Roboze Solutions for Metal Replacement

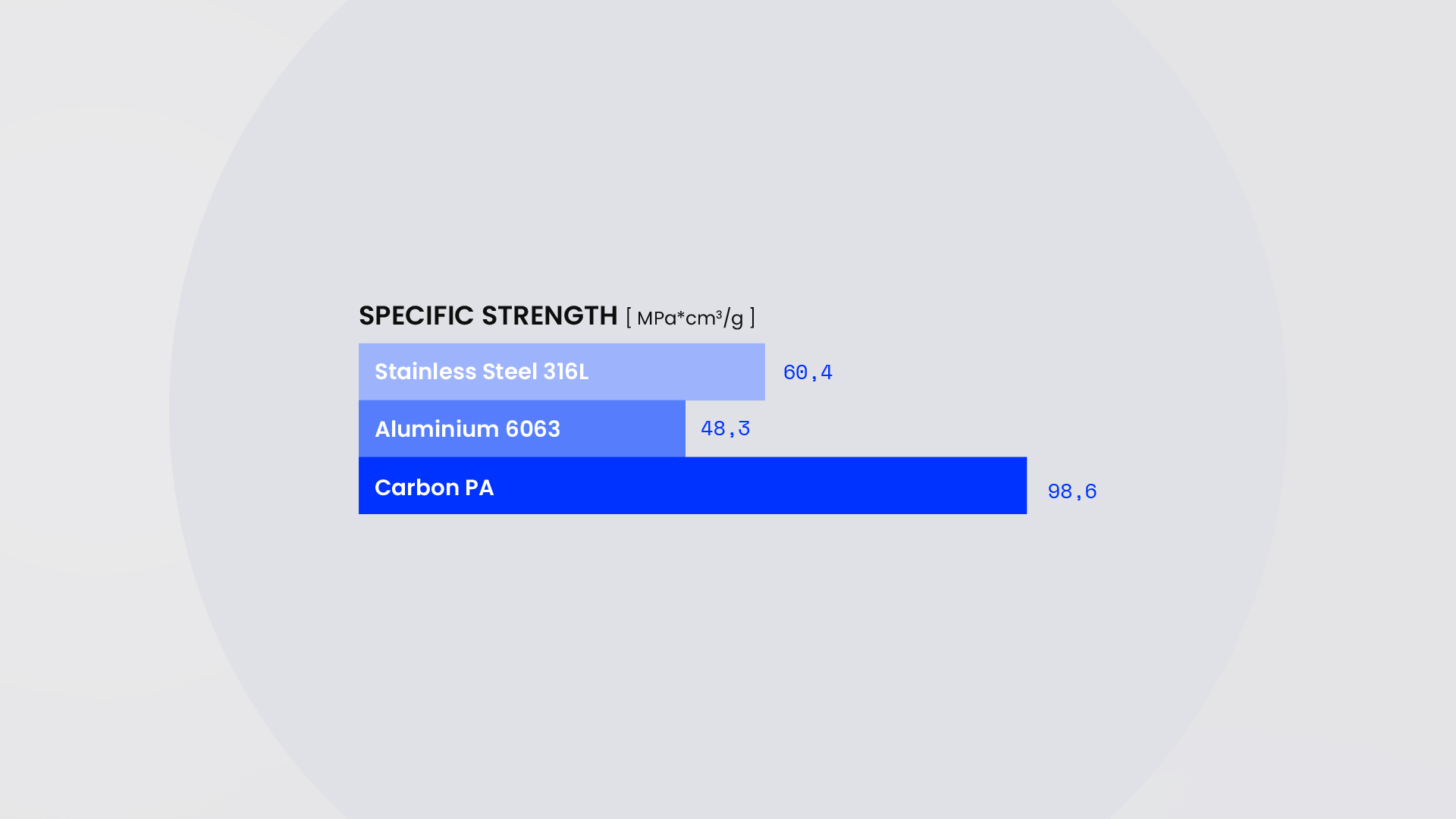

Since our very first steps into the 3D printing market, Roboze solutions have been designed to work with a wide range of both amorphous and semi-crystalline polymers, with particular attention to superpolymers and composite materials such as PEEK, Carbon PEEK, ULTEM ™ AM9085F, and Carbon PA.

By exploiting the unique properties of these plastics such as lightness, thermal and electrical insulation, chemical and mechanical resistance up to high temperatures, it is possible to replace metal in the most extreme working conditions.

However, to enable its use in industrial contexts, 3D printing must guarantee precision, repeatability, process control, good production efficiency and very low downtime.

The Roboze Automate technological ecosystem encompasses all of this. On one hand, it holds the best-patented technology supported by industrial automation systems with PLC logic, on the other hand a wide know-how in materials science and a team specialized in additive manufacturing helps companies all over the world to obtain functional pieces for end-use with certified superpolymers and composite materials.

Once repeatability and process control is ensured, when larger batches are requested, the production process can be distributed across multiple printers close to the point of use, scaling throughout.

Increased competitiveness, improved business reputation, productivity, and increased profits are direct benefits experienced by companies that have adapted Roboze innovation in response to technological acceleration and competition on a global scale.

Roboze ARGO Subscription Plan: how to obtain the most accurate 3D printing technology in the world for your company?

To help companies have easier access to these benefits, Roboze has developed the ARGO Subscription Plan, an innovative business model with an all-inclusive subscription formula that brings the world's most accurate 3D printing technology directly into your company along with support, warranty, materials and premium services included.

Contact one of our experts at info@roboze.com and get ready to print as strong as metal!