Jigs & Fixtures are special tools that are used to facilitate production (processing, assimilation and inspection operations) when the tool is based on the concept of interchangeability according to which each single part will be produced in a determined tolerance, creating a relation between J&F and machine tool.

Why are they so important?

- The J&F are used to reduce the manufacturing costs as they’re not included in the production core, but they reduce the setting time of the machine tools.

- Increase production

- Guarantee high precision of the printed parts

- Enable the processing of heavy and complex shaped parts

- Partially automate the tool

- Ensure interchangeability

- Increase the occupational safety, reducing accident risks

3D printing: what are the advantages?

- Considerable reduction of costs

- Reduction of supply time procurement times

- Freedoma to change the geometry according to the needs without any significant cost variations

- On-demand production, reducing the limited inventory space

- Environmental sustainability thanks to the reduction of the material waste, during the manufacuring process.

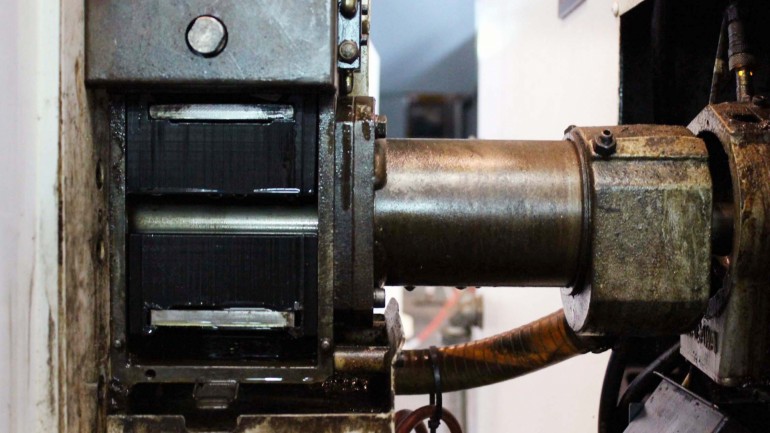

The Case: Direct manufacturing of a guide bar for bar holder

Operating requirements of the part

- Chemical resistance to oils

- Abrasion resistance

- Wear resistance

- Easily interchangeable depending on the bars' diameters.

Component printed with Roboze One vs Purchased component

Roboze is manufacturer of industrial/professional 3D printing solutions, that are designed and produced for your manufacturing needs.

Discover how to improve and optimize your processes in a perspective of accessibility and efficiency of your products' lead time.

Get in touch with our experts and do not miss the chance to increase the value and the performances of your company.

Your customers can't wait for it!