Accelerating the development of its revolutionary recycling system with the on demand production

Gr3N Recycling is a company operating in the development of solutions for the recycling of plastics, with a particular attention to revolutionary systems for the decomposition of PET, aiming at solving the problem of pollution caused by the plastic products dispersed in the environment.

In collaboration with leading companies in the chemical processes market and with the aim of concluding the first pilot plant by the end of 2020, the company is working on the development of a reactor that uses microwaves in an innovative way to depolymerize plastics in their basic components: monomers.

GR3N Recycling’s need, Roboze’s solutions

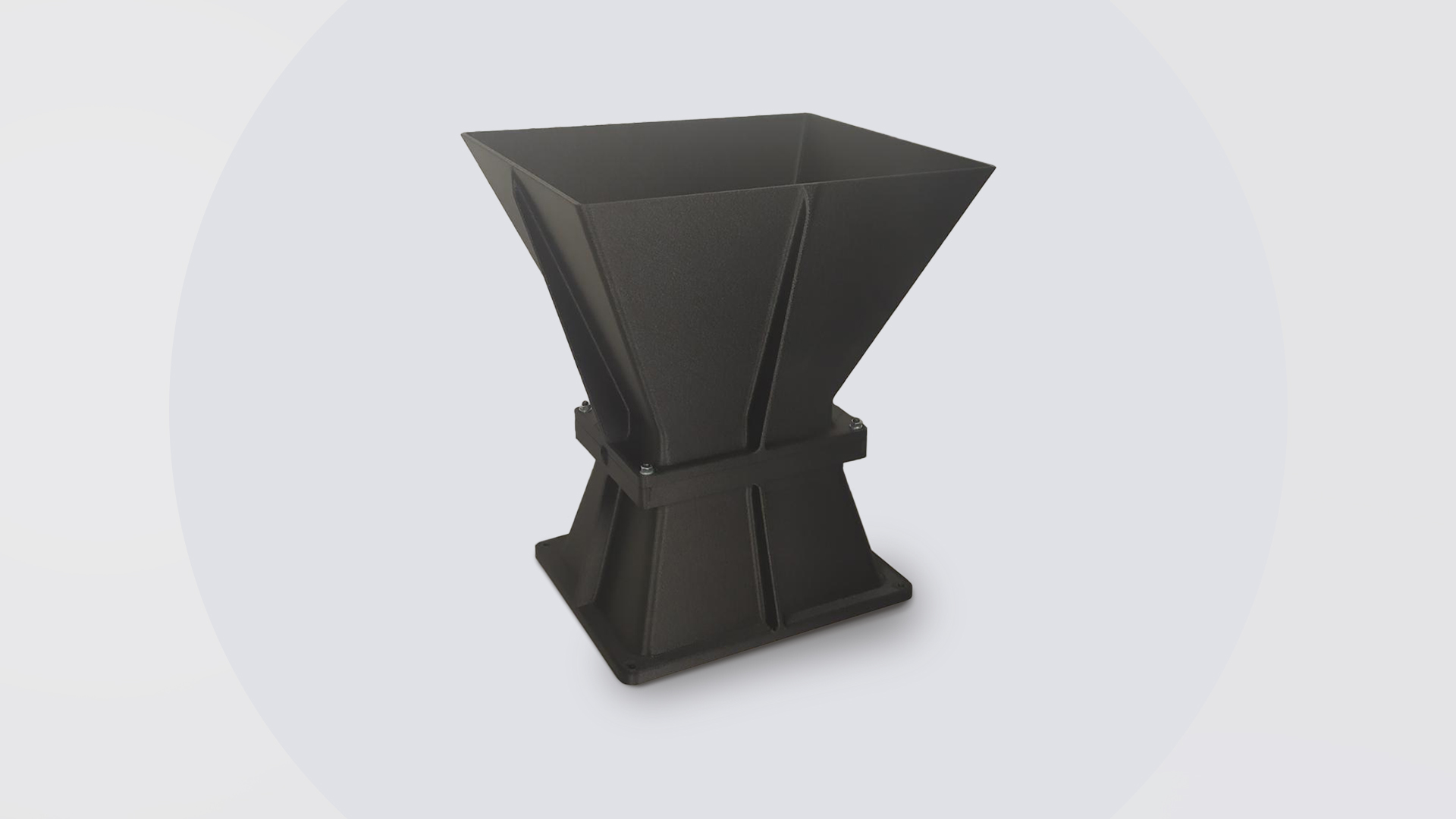

The tech department needed to produce a single part to be inserted in the machine system, useful for conveying the material to be recycled towards processing with the microwaves.

For the realization of this part, it was necessary to print the top with a dimension of 290x248x225mm and the base with a dimension of 245x205x130mm.

Roboze 3D Parts solution

“We chose to produce the part through additive technology as the alternative was the injection moulding, an extremely expensive process, both in terms of time and costs”

“Moreover the geometries, not totally regular, have pushed us to look for a solution that could meet our needs"

(Maurizio Crippa from GR3N Recycling)

After a deep research and selection by the technical team, GR3N Recycling chose, among the different alternatives on the market, to ask the support of Roboze 3D Parts.

The reliability of Roboze 3D printers, the production technology and the support received from the 3D Parts team have been variables that definitely influenced Gr3N Recycling in its choice.

“The 3D parts team has respected and analysed our needs and operating conditions of the parts, studying together with us the best approach for choosing the most suitable material optimizing the process and the final assembly.

The part completely met our expectations and the required standards while accelerating our testing phases”.

(Maurizio Crippa, from GR3N Recycling)

Get in touch with one of our consultants for further information: info@3dparts.com or start now to realize your projects through the Roboze 3D Parts platform.

#PrintStrongLikeMetal #OnDemand