Electric Cars and Electrical Mobility: The Needs of a Fast Growing Market

The transportation sector is experiencing a time of profound revolution. Cars, trams and trains are increasingly subject to changes, evolutions, innovations.

Until recently, cars only refueled with gasoline or diesel, but now they can rely on methane or GLP, but the future will inevitably see the spread of electric cars that are already gaining significant parts of the market today. The global market share of electric cars reached a record 2.6% in 2019, expanding into all major markets. More and more governments are politically committed to convert all cars in the territory from gasoline to electricity with short-term conversion goals. Netherlands and Norway are in pole position with the aim of achieving the transition to electric cars by 2025.

However, continuous evolution must be supported: new ideas lead to new designs to be validated and new needs to be met since it is important, once an innovation has been introduced, that all the other components of the vehicle are prepared so that everything works perfectly.

Electrical Mobility, optimizing processes and reducing production times with Roboze 3D printing

Traditional manufacturing does not always respond efficiently to these needs, as adaptation often requires time and large investments. 3D printing turns out to be a suitable solution to meet these requests as it allows to optimize processes, reducing the timing of realization. Through the Roboze functional rapid prototyping, it is possible to create new designs, testing and modifying them immediately in order to obtain a fluid and linear but above all fast process.

What are busbars?

Busbars are an increasingly present component inside our cars, as they are used to transfer energy from the battery pack to the electric motor.

Together with other parts that make up the power electronics of a vehicle, it is essential to ensure not only proper electrical insulation, but also good resistance to vibrations and high temperatures (over 100 ° C).

For this reason, in order to ensure maximum safety and avoid deformations, failures or short circuits, it is essential to use materials that ensure a reliable final performance when using these components.

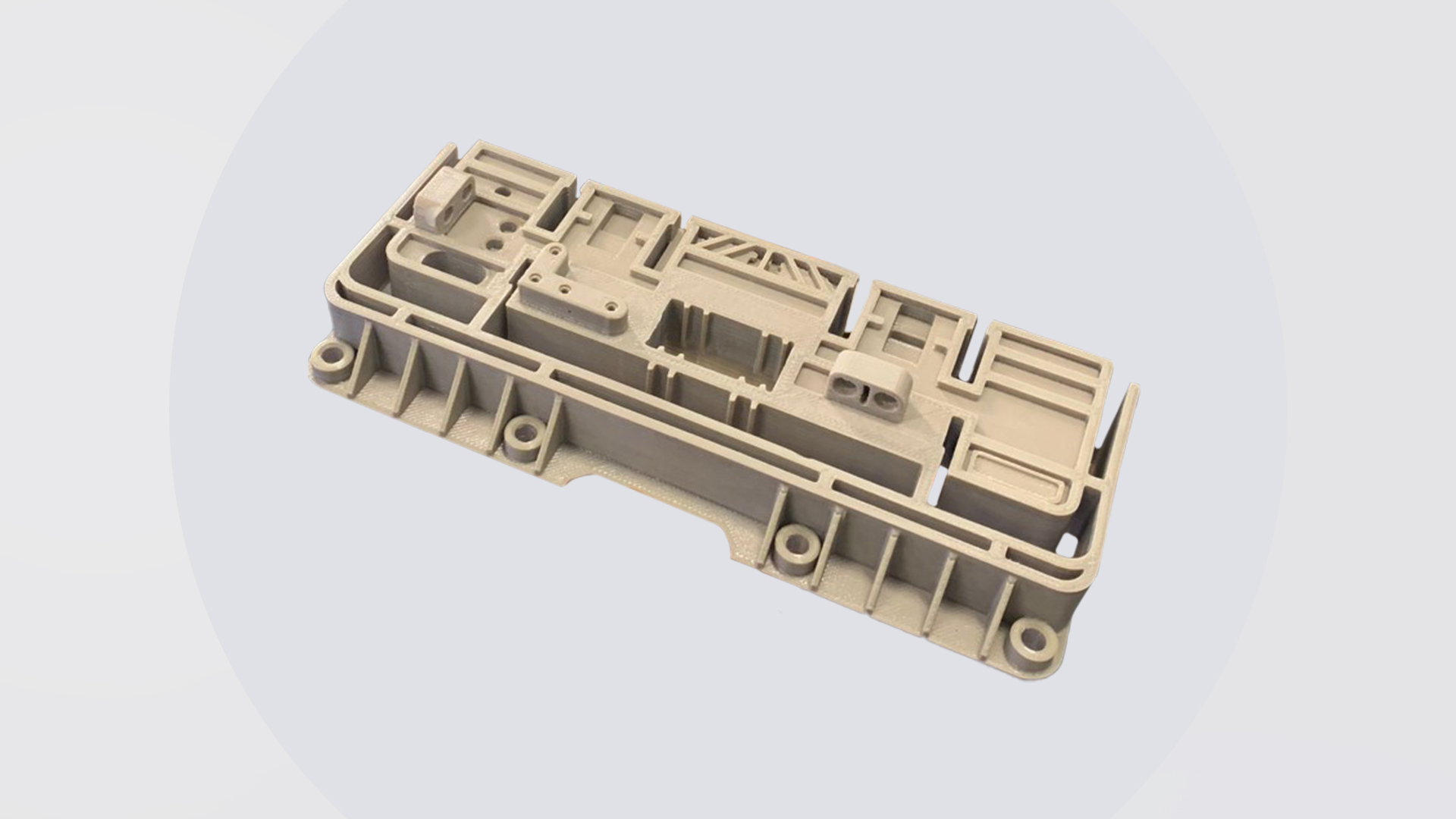

The busbars require the use of supports to maintain the correct position once the bars have been positioned, also useful for cooling them and creating joints for a homogeneous allocation of the electricity.

Busbar supports with PEEK 3D Printing. The Roboze solution

The supports can have different geometries and be produced in different materials as long as they ensure high mechanical and thermal resistance.

Thanks to Roboze 3D printing it is possible to produce busbar supports in PEEK, a high performance material that guarantees volume resistivity at 23 ° C of 1016 Ohm cm for greater safety in the event of high voltages. Roboze PEEK is classified as a self-extinguishing material, has a low hygroscopicity, an elastic modulus up to 3.3 GPa and an HDT of 150 ° C ensuring safe operations.

The Production Series printers, ARGO 350 and ARGO 500, allow you to optimize the production of these parts by customizing them according to specific needs and use without additional investments, avoiding to adapt production each time according to the geometry.

The advantages of Roboze additive manufacturing translate into concrete savings in terms of production costs and times, as it is possible to produce On Demand and Just in time parts whenever needed, without the necessity of a physical warehouse.

The benefits associated with the use of Roboze 3D printers also concern the wide range of high performance materials such as PEEK: the chemical, mechanical and thermal characteristics of this super polymer, as previously described, ensure productions that meet quality standards even in very demanding sectors.

To encourage the adoption of a new manufacturing model aimed at distributing production around the world by bringing it back to the point of use, Roboze has introduced ARGO Subscription Plan, an all-inclusive formula to accelerate ROI and immediately obtain value through a personalized program based on an annual subscription, allowing companies to optimize their financial resources, moving from a CapEx model to an OpEx model, to the advantage of greater organizational flexibility.

The new solution, designed to support innovators around the world, allows access to ARGO 500 along with exclusive services, engineering support, high performance materials, warranty and continuous software updates, so that selected companies can focus on production while Roboze takes care of the rest.

Visit the dedicated page to find out more.

#PrintStrongLikeMetal #OnDemand