Additive Manufacturing and Carbon PA: 3D printing of a fixture for welding

Personalize the production processes through additive manufacturing

Additive Manufacturing offers great advantages in the industrial production processes thanks to the possibility to realize conceptual and functional prototypes and finished parts with reduced time and costs compared to the traditional manufacturing methods.

Precision, versatility and resistance: the 3D printing advantages

3D printing allows to realise tools that are extremely important within the production chain, like for example fixtures that require precision and high mechanical resistance. Roboze FFF 3D printing technology offers all these advantages thanks to a wide range of techno polymers having high mechanical, thermal and chemical properties: an example is Carbon PA, one of the strongest materials, with the greatest mechanical performance in the polymer 3D printing field. Thanks to its 136 MPa tensile strength, 15 GPa elastic modulus and 200°C HDT, Carbon Pa is ideal for a personalized realization of resistant, long-lasting and versatile tools.

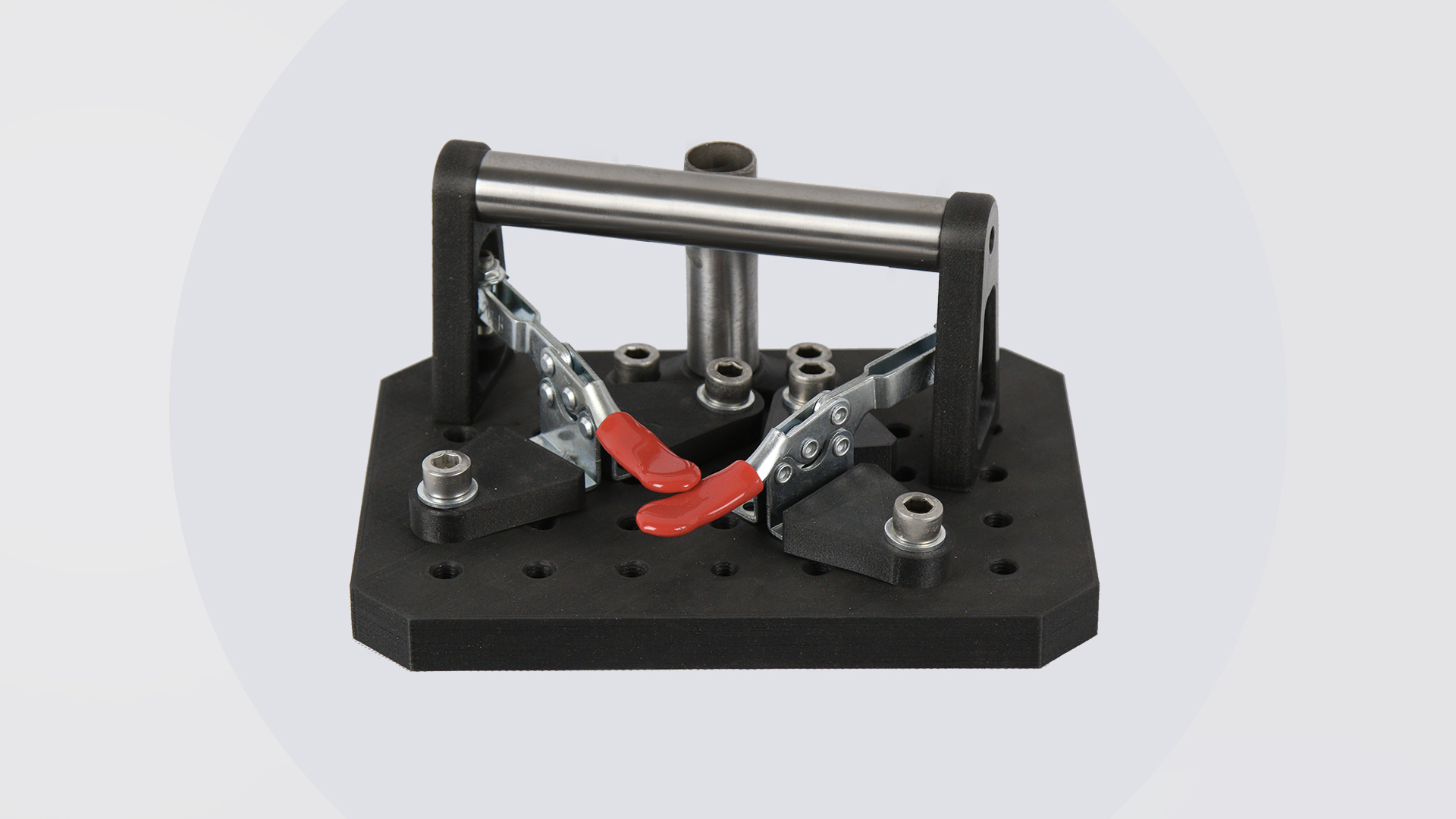

The fixture for welding in Carbon PA, the latest Roboze creation

Roboze team has realized a fixture for welding in Carbon PA, useful to keep the parts to be welded fixed, managing to reduce production time and costs. With the traditional manufacturing methods, the production cost is definitely higher, considering the necessity to level, drill and thread the components of the fixture. Thanks to Roboze 3D printing technology it is possible to reduce the production costs up to 80%.

Carbon PA and 3D printing represent, therefore, the right compromise between resistance and production affordability, allowing to rationalise costs and personalize the fixture during the design and realization phase.

Get in touch with our experts for a personalized consultancy and get ready to print strong like metal. Email at info@roboze.com.

#PrintStrongLikeMetal