The issue of accuracy and repeatability in 3D printing

The theme linked to the repeatability and accuracy of printed parts engages the most passionate and commits manufacturing companies to find solutions to solve this important issue. Even though 3D printing started as a means for rapid prototyping, the maturation of the technology and the development of new materials has allowed 3D printing to become a valid manufacturing method for functional parts.

A technology is only useful for industrialization if it is both scalable and reliable when dealing with larger part volumes. This translates to a need for accuracy and repeatability that is comparable to that expected from any manufacturing technology; so, the same 3D printed part several times must meet the required tolerances every time (whether dimensional, mechanical, or otherwise).

All the limits of traditional 3D printing with FFF technology

There are several factors that cause small differences and inaccuracies in parts printed with traditional FFF (fused filament fabrication) printers including:

- Process parameters: this includes settings that can be changed in slicing programs (such as layer height, extrusion multiplier, in-fill type and percentage) and other factors such as the choice of material, extruder type, film used, and part geometry. Process parameters also often need to be adapted from one part to another;

- Process control: these include ensuring a constant temperature for the extruder and build chamber, having an even airflow that reaches all parts, the position of the part(s) in the build chamber, and the use of different printers.

Given the large number of potential sources for errors, achieving conformity across build jobs and 3D printers is a difficult endeavor but one that Roboze has met head-on.

Roboze technological ecosystem in the most accurate printers in the world

The technological ecosystem has been developed with the aim of producing the most accurate and automated printers in the world. The development of this project has led to the birth of different technologies and methodologies to ensure repeatability and accuracy across the entire range of Roboze printers: from the heated chamber that guarantees homogeneous heating throughout the build volume (watch the video here), to the patented Beltless system that has made belts obsolete, to the dedicated high-viscosity polymer (HVP) extruder, to the HT filament drying system. To find out more go to the dedicated page.

Study of the accuracy and repeatability with Roboze 3D printers

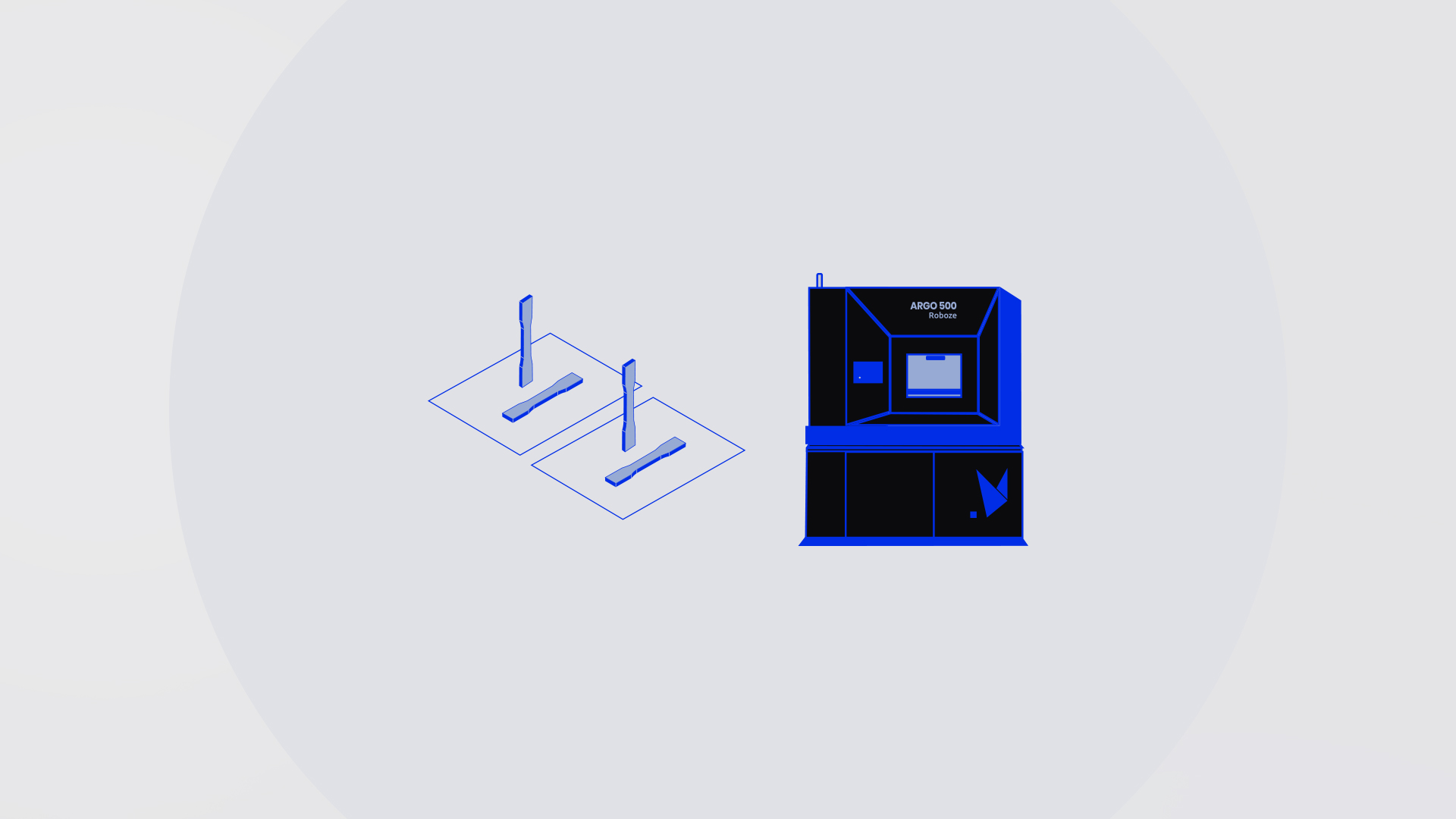

Roboze has conducted a representative study to demonstrate that geographical location, operator, printer, and position in the build chamber does not affect the parts produced. The details of the study are:

- The samples were printed in different locations of the build plate to measure the consistency within the same printer;

- Three sets of samples were produced on every printer to measure the repeatability between jobs;

- Two ARGO 500 printers were used, one in Bari and the other in Houston, to measure the repeatability between different machines.

After 3D printing, the samples were separated from the polymeric film and measured on three axes corresponding to the printer axes (X, Y, Z) without any post-processing. The measurements were then compared to the STL values to determine the accuracy and repeatability of the 3D printers. The results of the study are discussed below.

Study findings

Analyzing the over 900 measurements made on the three axes of the samples it is possible to see that the measurements are always within the medium tolerance class according to ISO standard 2768. An example is shown in figure 1 where the measurements are compared to the nominal STL values in all three dimensions. As demonstrated by the overlap of the mean and median and the similar size of Q3-median and median-Q1, the distribution is always balanced.

To have a better idea of the statistical dispersion of the data and to better understand the repeatability of the process, a histogram has been generated demonstrating the standard deviations of the various sets of measurements, see figure 2. The chart shows that the standard deviation for 83% of measurements is below 0.04mm and 56% for 0.02mm. In general, the standard deviation is small, demonstrating how the Roboze technological ecosystem positively impacts the consistency of the 3D printing process.

The advantages of Roboze Automate ecosystem for manufacturing companies

The development of Roboze 3D printing technology has seen years of research and strategic partnerships, all of which are focused on industrializing additive manufacturing to allow access to the production of finished parts throughout the world. The innovative elements and industrial automation of the Roboze Automate ecosystem become a critical success factor for companies as they are able to provide:

- repeatability of operations;

- production flexibility;

- total process control;

- traceability;

- greater safety.

All of these core components maintain a continual focus on optimizing resources, costs and improving production management.

Trust our experts and find out how you can accelerate your digital transformation with an accurate and scalable 3D printing system. Contact us today at info@roboze.com and get ready to #PrintStrongLikeMetal with Roboze!