5 reasons to choose industrial 3D printing to transform your production

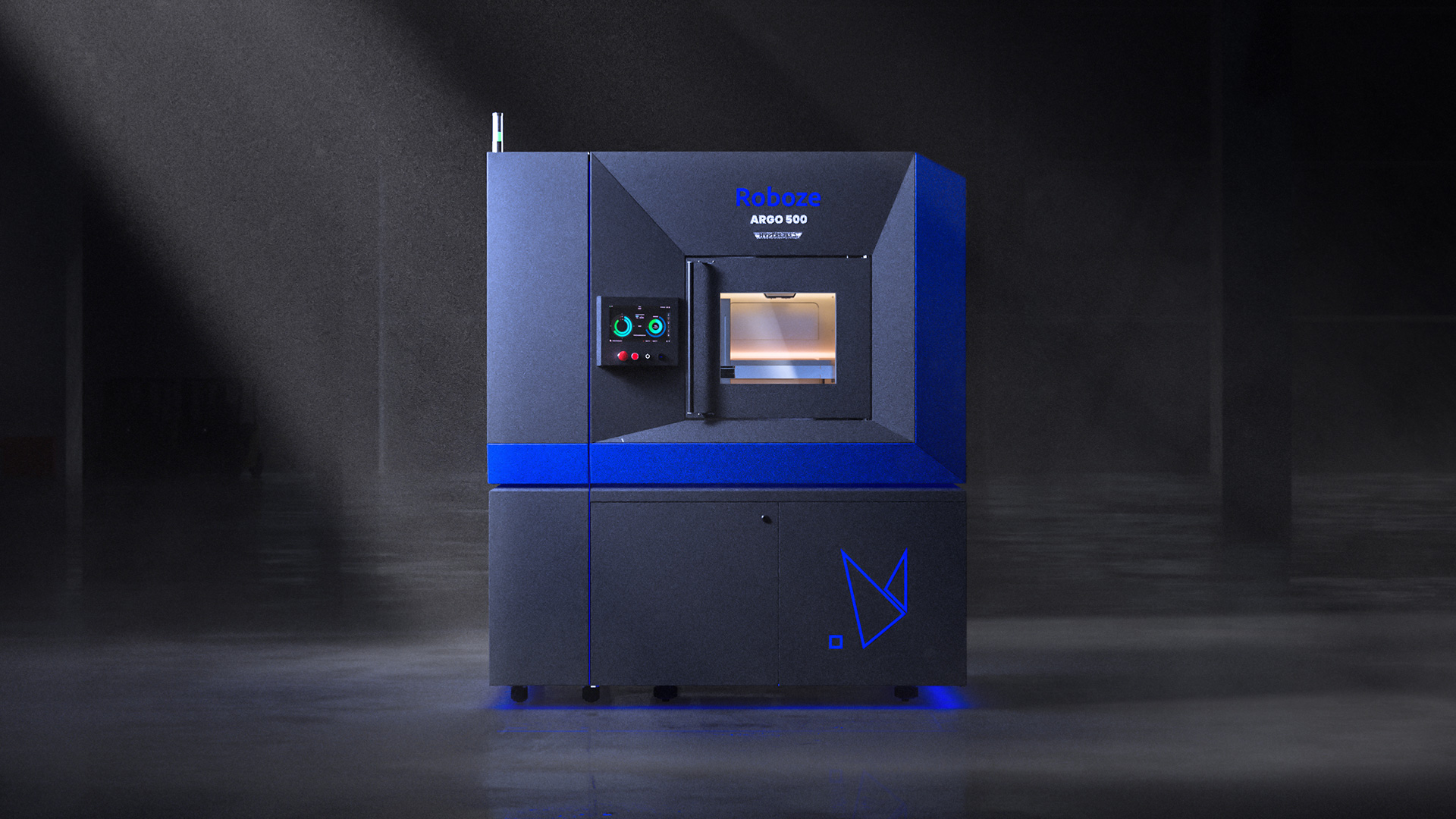

Industrial 3D printing is no longer just an emerging technology; it has become an established reality that is redefining how companies design, prototype, and manufacture components in critical sectors like aerospace, mobility, and energy. Roboze, with its advanced manufacturing solutions and innovative materials, is leading this transformation, helping businesses enhance their operations and become more competitive.

Let’s take a closer look at five key reasons why you should consider adopting industrial 3D printing.

1. Customization of Parts

In traditional industrial manufacturing, creating customized parts with complex geometries often leads to high costs and long lead times. Additive manufacturing eliminates these limitations, offering the ability to produce custom components tailored to the specific needs of a project, whether it’s functional prototypes or final parts.

For example, in the aerospace industry, the ability to produce high-performance custom parts is essential for ensuring lightness and strength. With materials like Roboze’s PEEK and Carbon PEEK, companies can create complex components, minimizing weight without compromising mechanical or thermal strength.

Discover how Roboze 3D printing has revolutionized the production of aerospace components in our dedicated section.

2. Reduction of Production Lead Times

The speed at which companies can move from concept to production has become a critical factor in many industries. Additive manufacturing accelerates this process, drastically reducing the time needed for prototyping and small-batch production. This means companies can respond to market demands faster, launch new products more quickly, and save valuable time.

For example, Roboze is supporting companies in the railway sector, such as Hitachi Rail, by optimizing the availability of spare parts through 3D printing solutions. This ensures rapid on-site production and reduces machine downtime.

3. Reduction of Production Costs

3D printing eliminates the need for expensive equipment like molds or specialized tools, significantly lowering the costs associated with traditional manufacturing. This advantage is particularly relevant when it comes to small production runs or highly complex parts. With industrial 3D printing, companies can produce exactly what they need, when they need it, without the high fixed costs of large-scale production.

In industries like energy, Roboze has demonstrated how it’s possible to produce custom, high-performance components at significantly lower costs compared to conventional methods, without compromising quality.

Watch the video on how Roboze supported Petroleum Development Oman in adopting industrial 3D printing with non-metallic materials for the production of 17 MW electric motor cooling system blades.

4. New High-Performance Materials

One of the main advantages of industrial 3D printing is the ability to work with advanced materials that meet extreme requirements for strength, lightness, and durability. Roboze is a pioneer in using materials like PEEK and Carbon PEEK, which offer exceptional properties for applications in harsh environments, such as high temperatures, chemical resistance, and the ability to withstand heavy mechanical loads.

In the electric mobility sector, the use of these materials has enabled the creation of lighter, stronger components, improving vehicle efficiency without increasing costs. This ability to enhance technical performance with innovative materials makes Roboze 3D printing an essential technology for the industry of the future.

Explore our advanced materials: find all the technical details in our materials section.

5. Sustainability and Resource Optimization

Sustainability is no longer just an option; it’s a necessity. Additive manufacturing helps reduce material waste by using only what is strictly necessary to produce the component. This not only lowers costs but also results in a smaller environmental footprint. Additionally, the ability to digitize production and create components on-site reduces emissions related to transportation and logistics.

Roboze, with its sustainability-focused technology, is helping companies worldwide optimize resource use and reduce environmental impact, especially in resource-intensive sectors like energy and mobility.

With its commitment to R&D in advanced materials and manufacturing technologies, Roboze is the ideal partner for companies looking to take the leap and lead the shift toward a more efficient and sustainable future.

Don’t wait any longer! Contact Roboze today to discover how our technology can transform your production.