SMART WEBINAR: Additive Manufacturing Certifications

May 28th at 5 pm (CEST) - 10 am (CDT)

The integration of additive manufacturing in the traditional production processes allows companies to reduce the lead-time of a product and increasingly control quality and costs of components within the manufacturing cycle. The replacement of metal parts with high temperature super polymers and composite materials guarantees significant advantages in all those sectors like Aerospace, Motorsport, Oil&Gas and Automotive that benefit from the reduction of components’ weights, the friction coefficients, the electrical insulation and advanced chemical resistance properties.

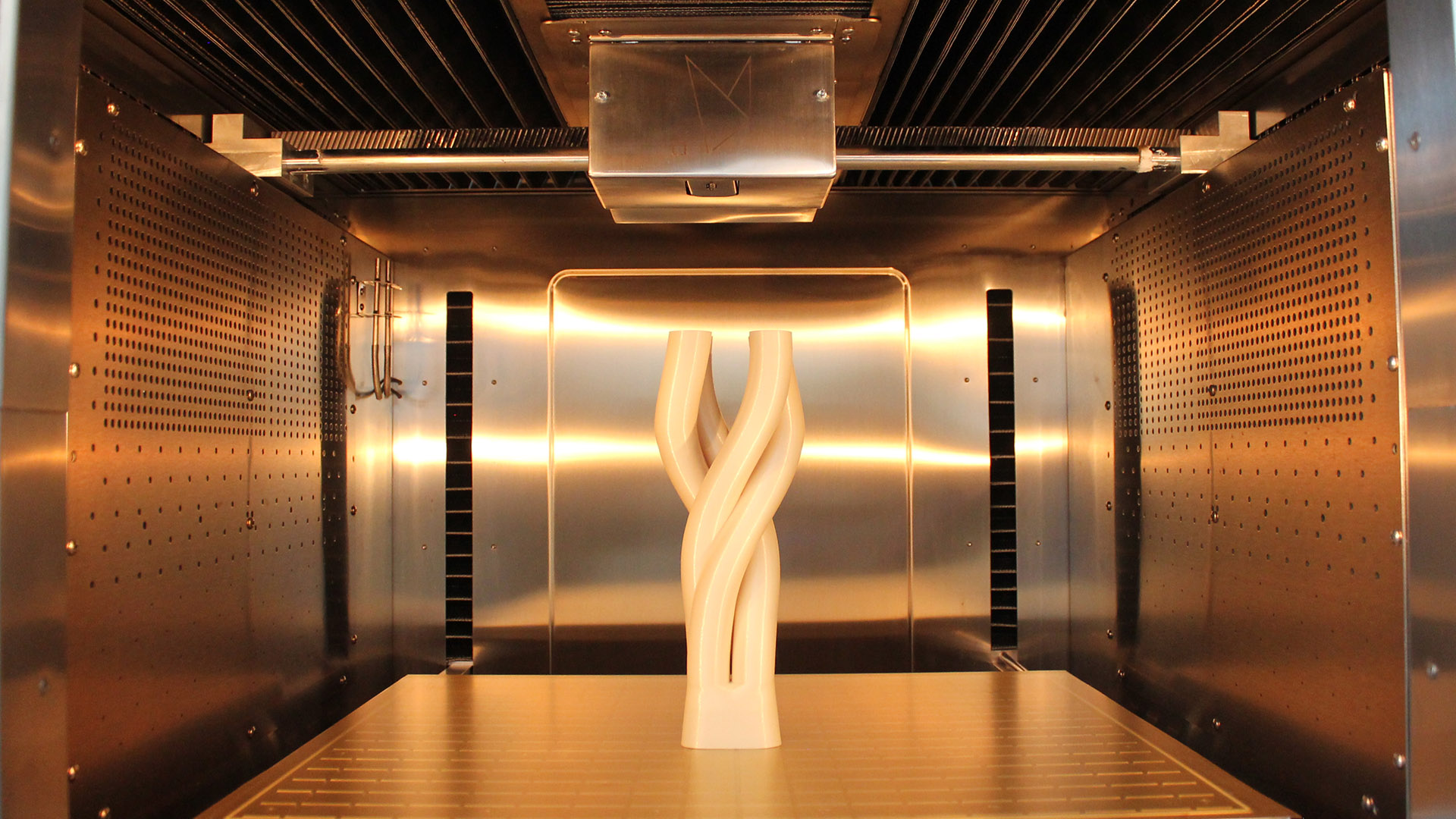

Additive Manufacturing, over the years, is becoming an increasingly important element for the manufacturing companies that intend to optimize their production supporting traditional methods, incapable to meet the new market’s needs. 3D printing, however, needs to demonstrate its capacities against these consolidated systems like molds, milling and turning, ensuring quality standards, repeatability and process control. Roboze additive manufacturing can meet the challenge by allowing the production of custom spare parts on demand and just in time, realizable with innovative materials and solutions, and with process control and quality that are repeatable over time.

In the next webinar we will talk about how important is the certification of the materials and the 3D printing process, with a particular focus on how Roboze can help its customers in this regard.

Join the webinar powered by Roboze on May 28th at 5 pm (CEST) - 10 am (CDT):

#PrintStrongLikeMetal