Motorsport

Break innovation records

Overview

Motorsport emerges as an authentic laboratory of innovation, where races play the role of testing ground for cutting-edge technologies and engineering solutions which subsequently spread to various sectors.

From the optimization of component geometries to the search for lightweight, resistant and sustainable materials, additive manufacturing and the use of advanced materials emerge as fundamental pillars, allowing extreme customization of components and improving the overall performance of vehicles, thus helping to shape the production panorama with an innovative approach aligned with the latest frontiers of technology.

Advantages

-

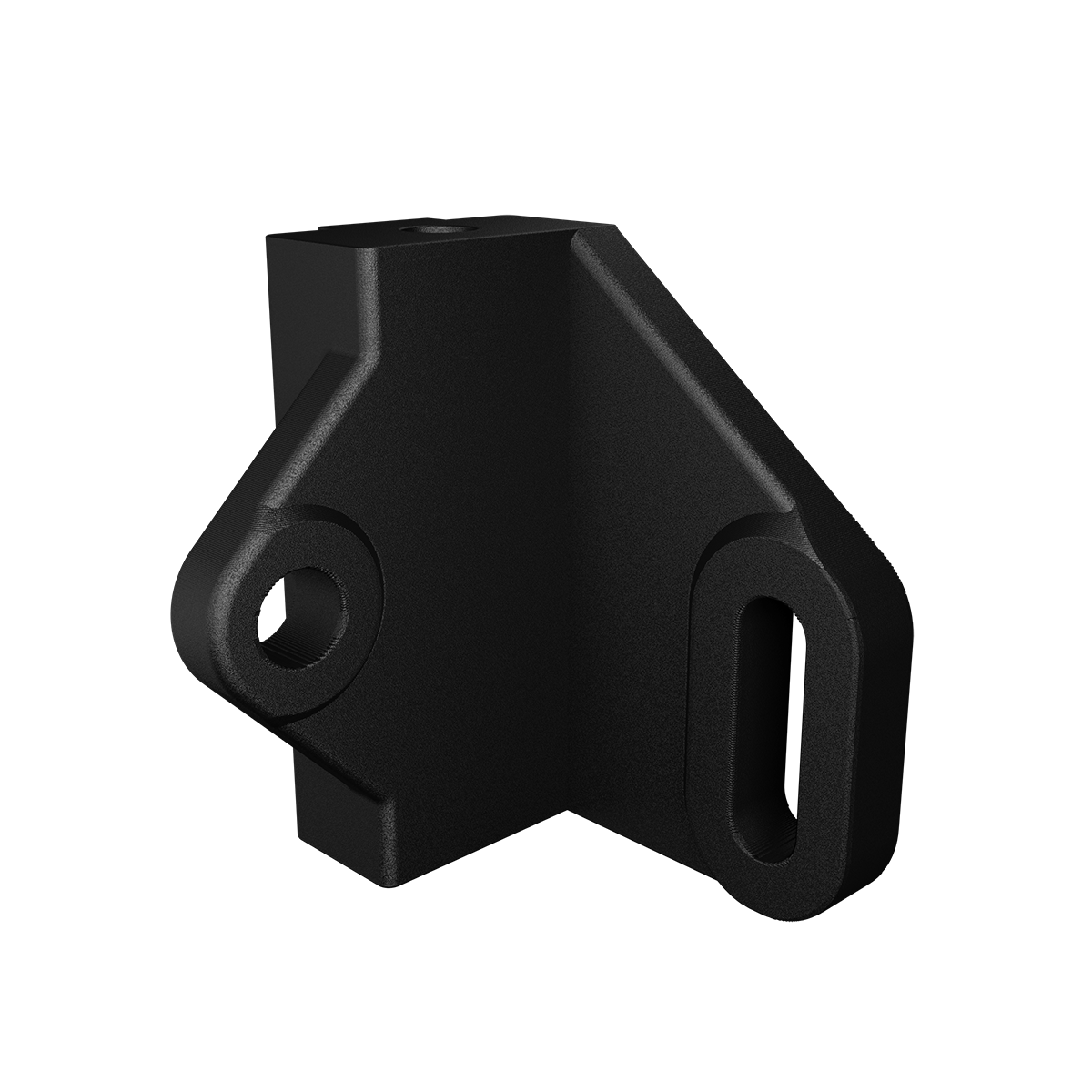

Custom components

Additive manufacturing allows the creation of highly customized and complex functional components, adaptable to specific requests. This flexibility translates into greater efficiency and improved performance

-

Increased performance on the track

The use of Roboze materials offers a combination of mechanical properties and lightness that improve the reliability and robustness of the parts, directly contributing to the increase in performance on the track during competitions

-

Reduction of development times

Roboze's additive technology enables rapid production, allowing operators to reduce development times. This provides greater flexibility in design and timely response to changing industry needs

Suggested material

Carbon PA PRO

Roboze Carbon PA PRO is one of the 3D printing materials with the highest mechanical performance. It is a carbon fiber reinforced polyamide, optimal for applications where high mechanical resistance is required. Thanks to its high tensile modulus, it represents the ideal choice for replacing light metal alloys.

Resources

Discover how Roboze is supporting the widespread use of additive manufacturing for the digital transformation of the Motorsport industry.

-

Improving performance on the track with 3D Printed Aerodynamic Components

Motorsport requires innovative and sustainable production solutions. Roboze 3D printing and composite materials such as CARBON PA PRO revolutionize the production of aerodynamic components, offering tangible advantages on the track. To find out more, download the full document.